PRODUCTS

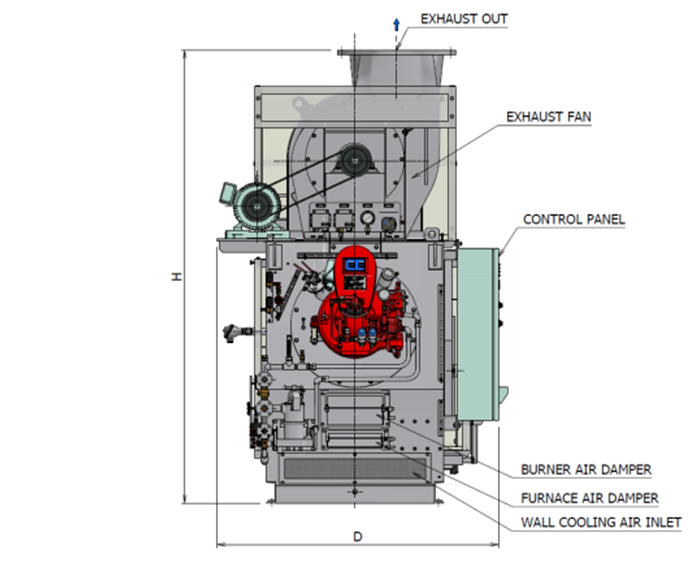

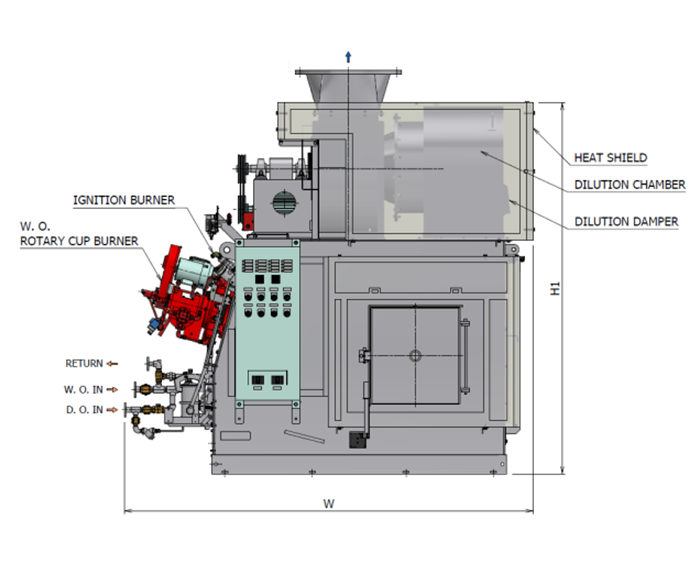

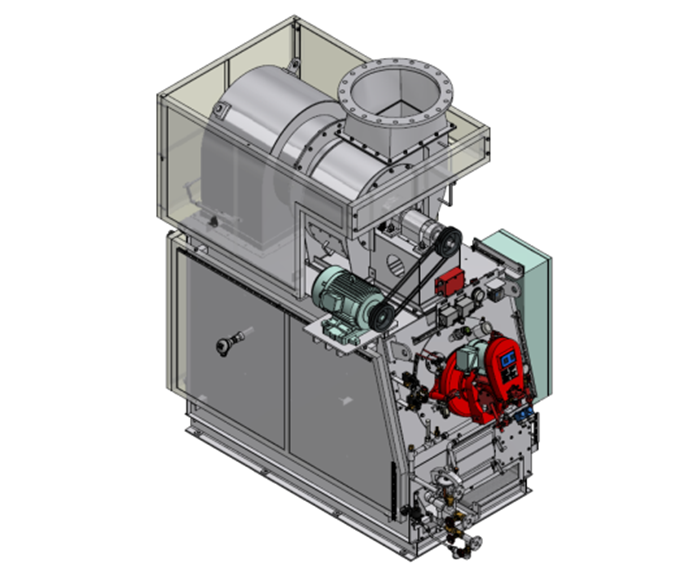

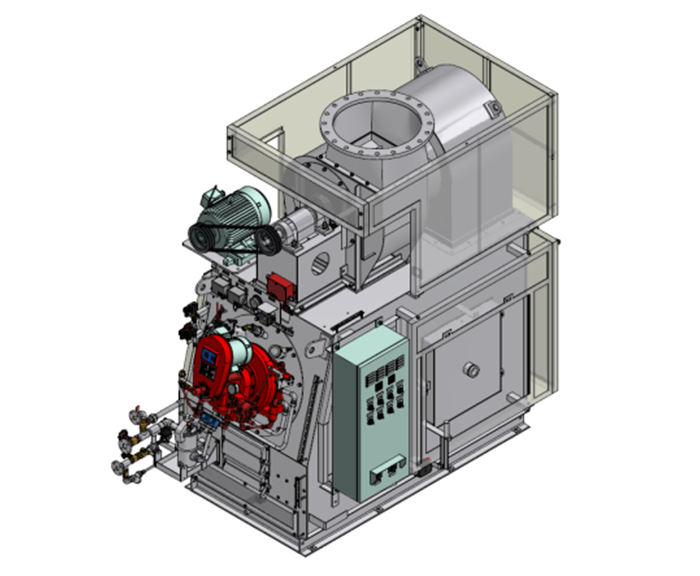

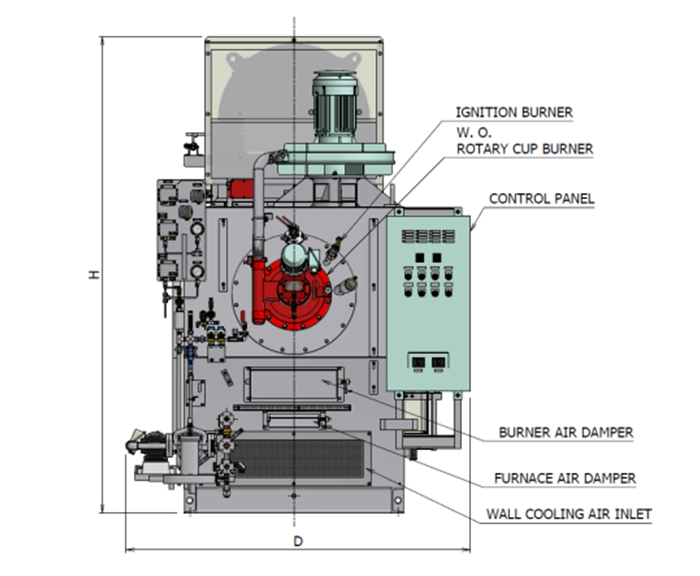

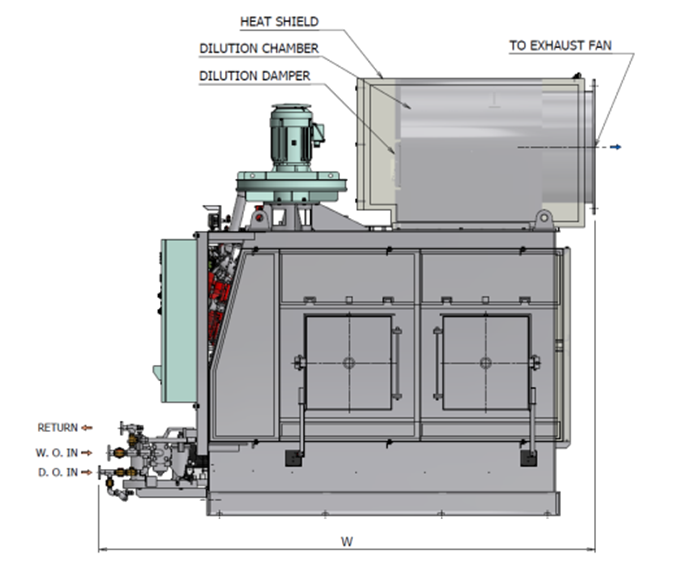

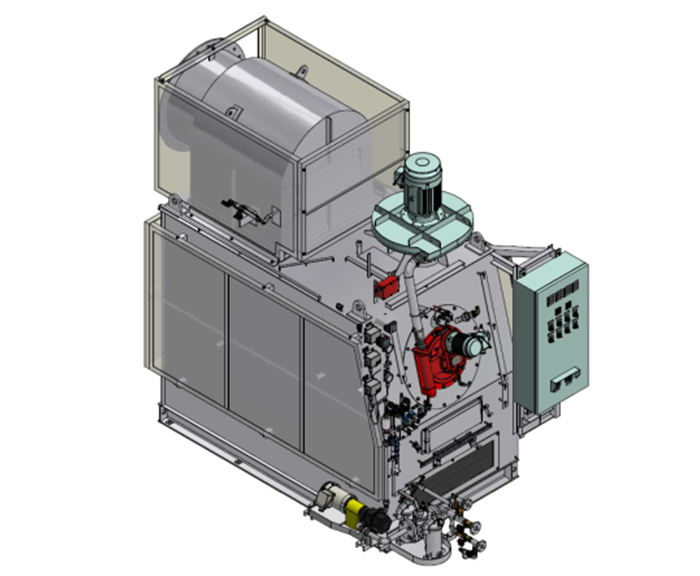

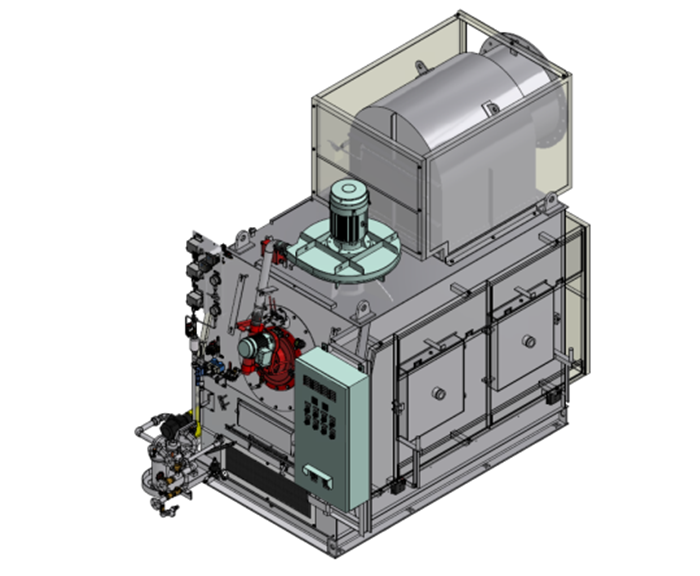

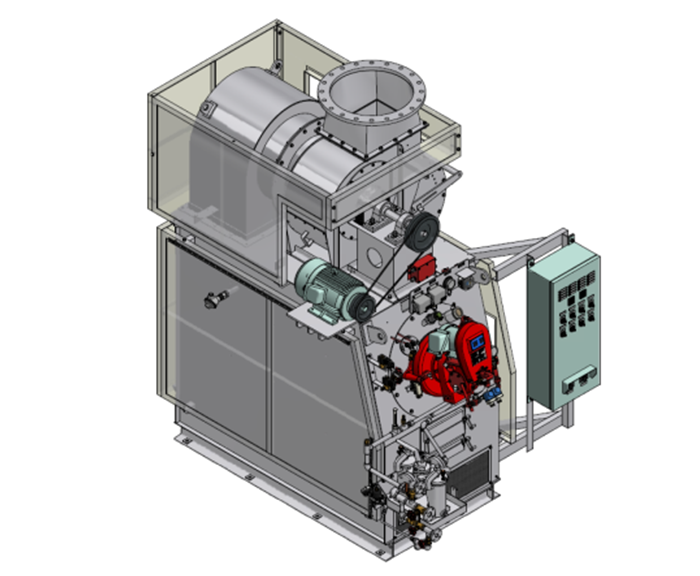

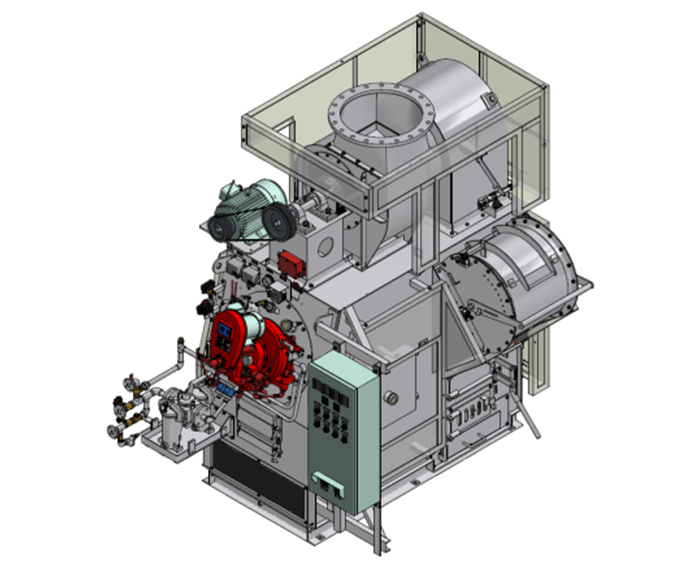

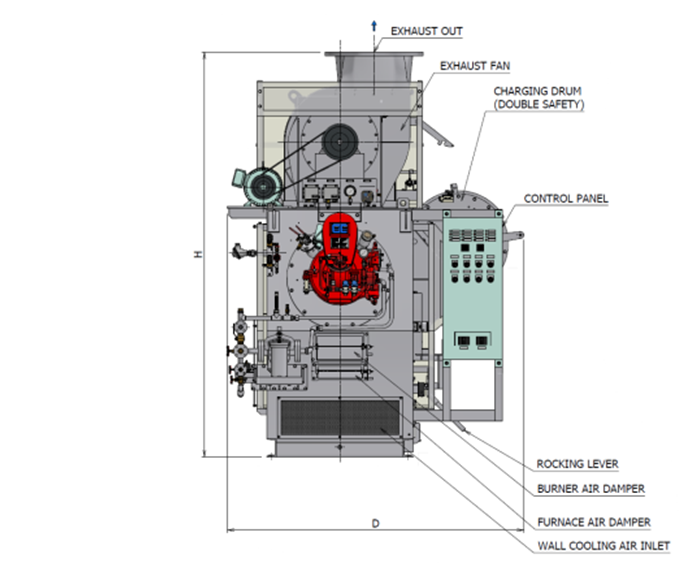

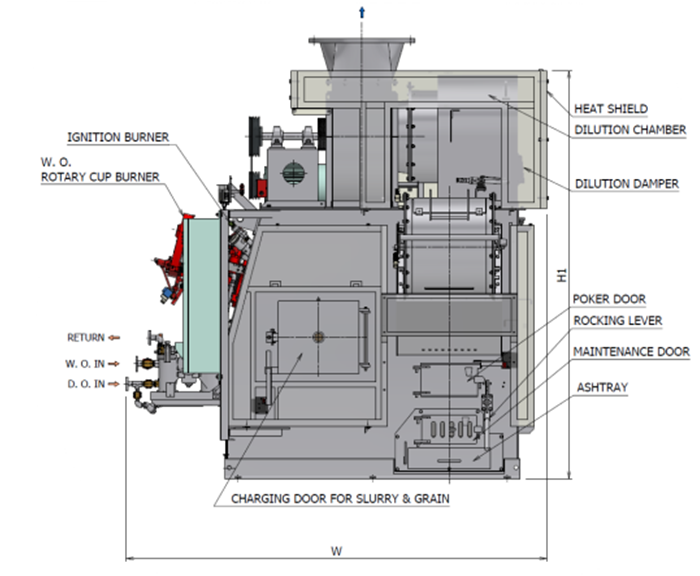

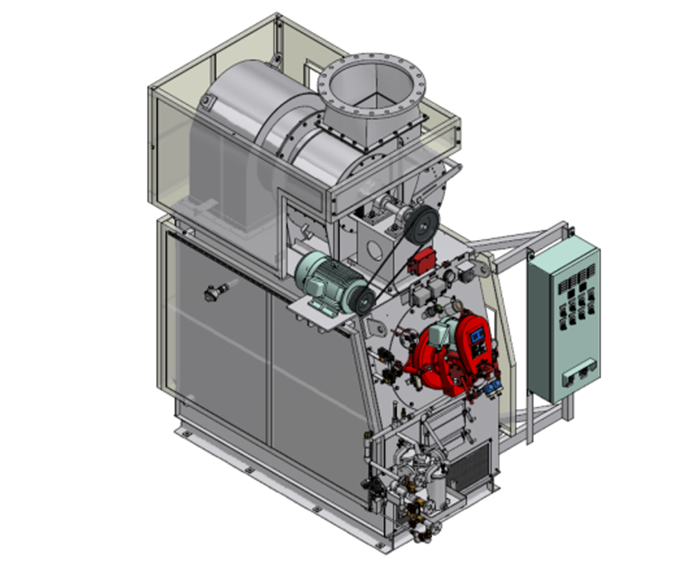

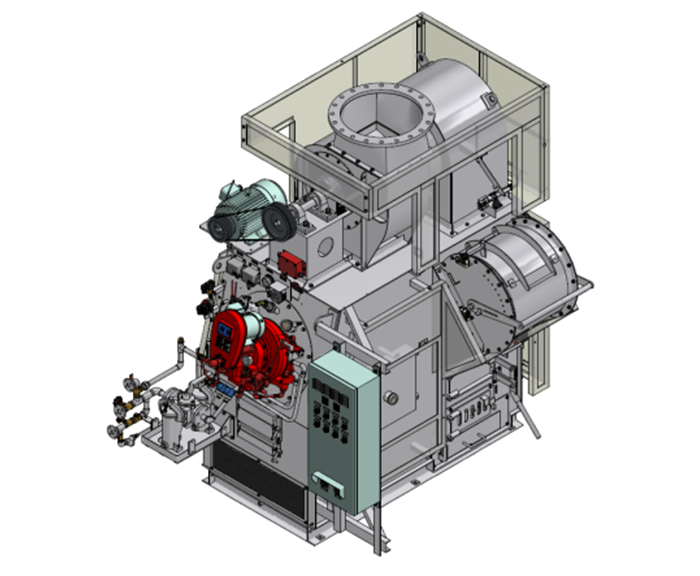

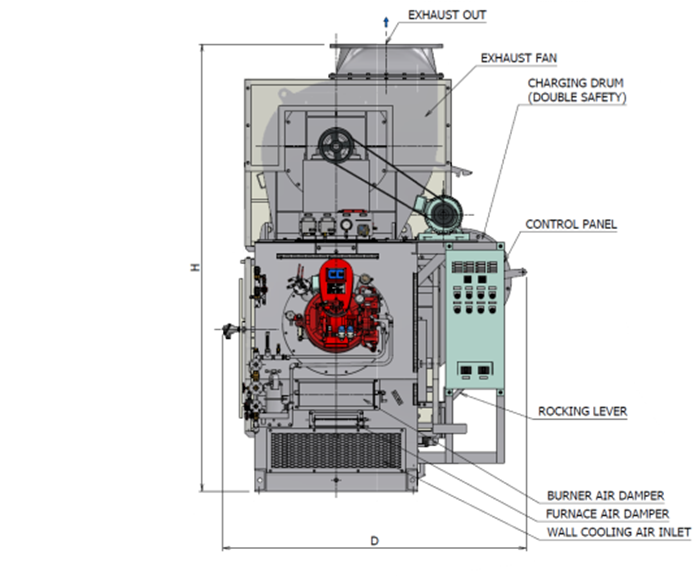

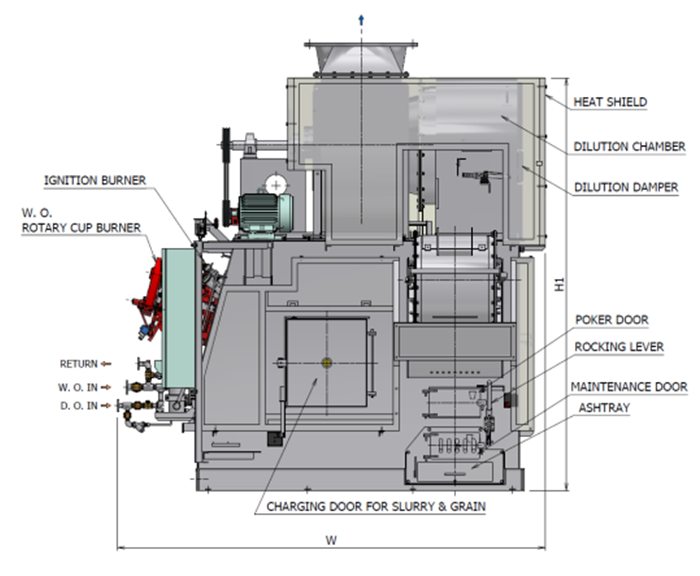

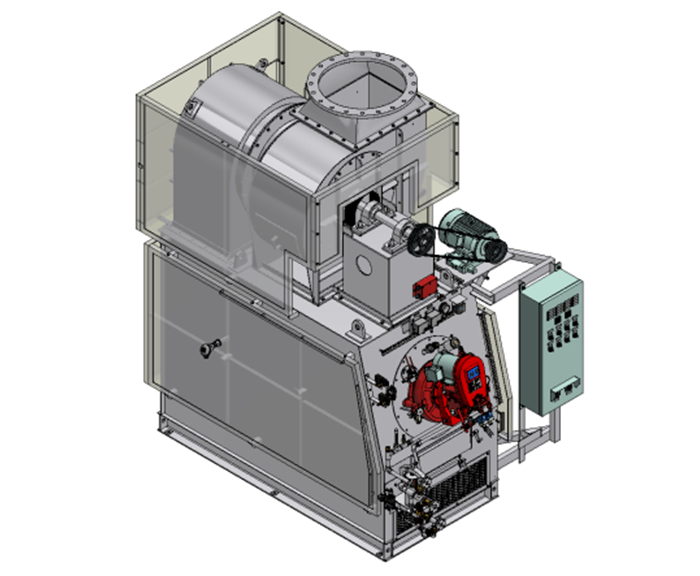

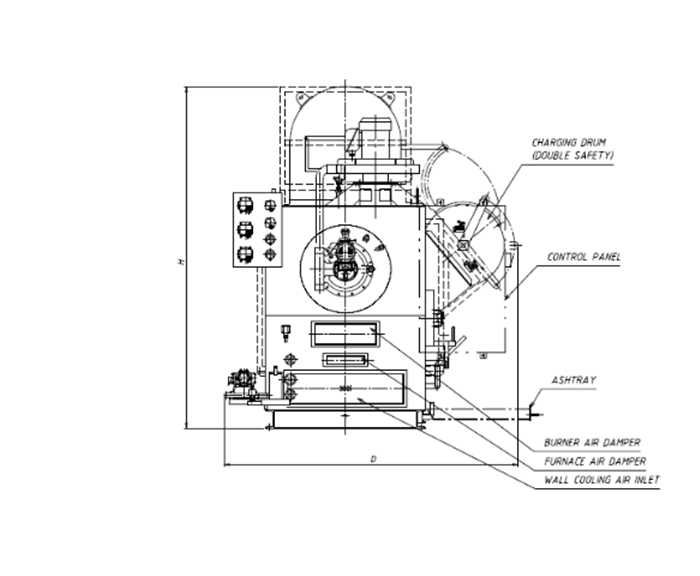

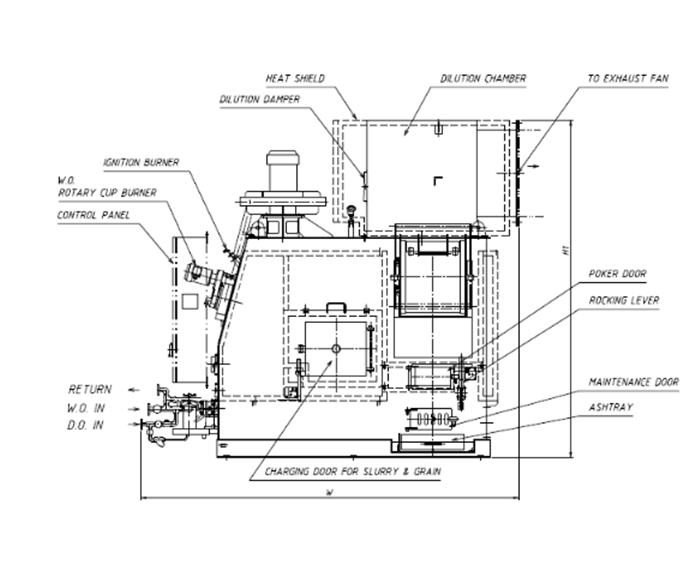

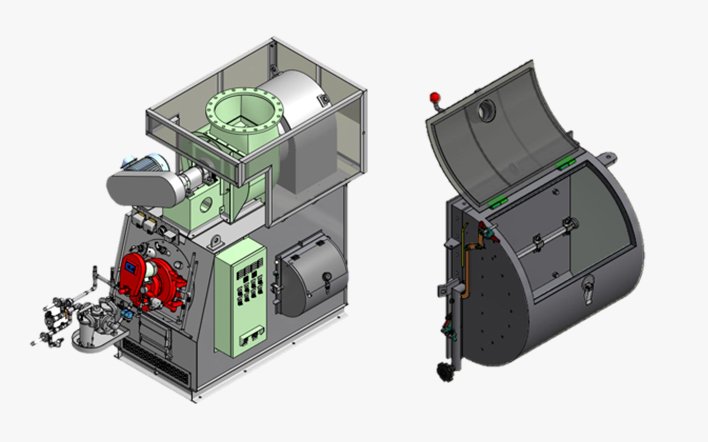

Marine Incinerator

Efficient waste disposal with reputable combustion technology

What is a marine incinerator?

A marine incinerator disposes of domestic wastes and operational wastes generated on board as well as oil residue.

Pollution by garbage from ships is regulated by MARPOL 73/78 Annex V. Stricter measures took effect after the amendments in 2013, which prohibited the disposal of almost all garbage other than food waste into the ocean. The use of a marine incinerator is becoming more important as the demand for environment-conscious garbage disposal rises.

Sunflame's marine incinerators enable environment and crew-friendly waste disposal. The combustion technology cultivated in our auxiliary boiler burners effectively disposes of oil residue with uncertain quality. Environmental burden is minimized as assisting combustion is almost unnecessary. The marine incinerator also contributes to efficiency of ship space and unloading cost by incinerating solid waste, including plastic waste.

Advantages

-

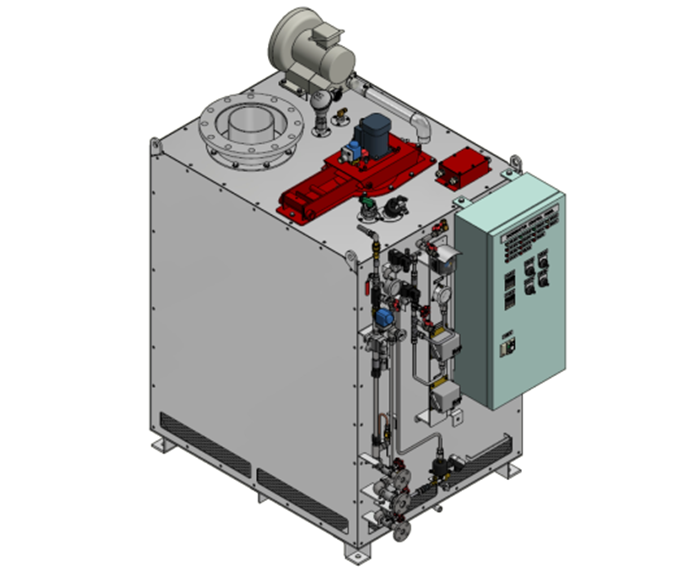

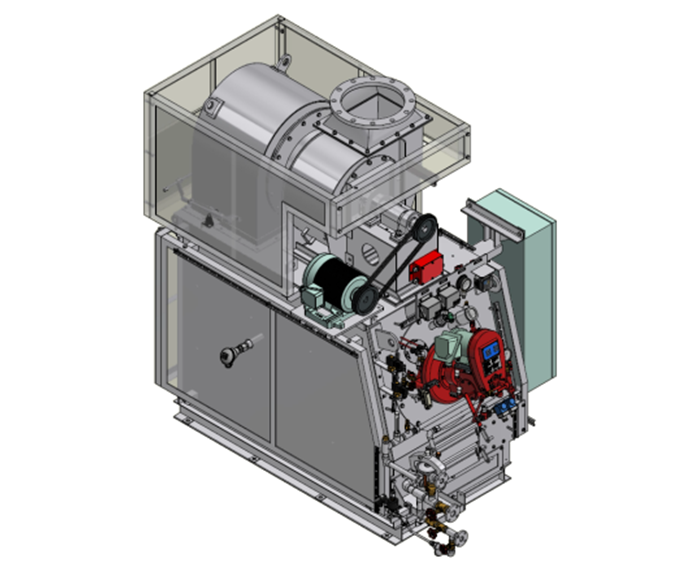

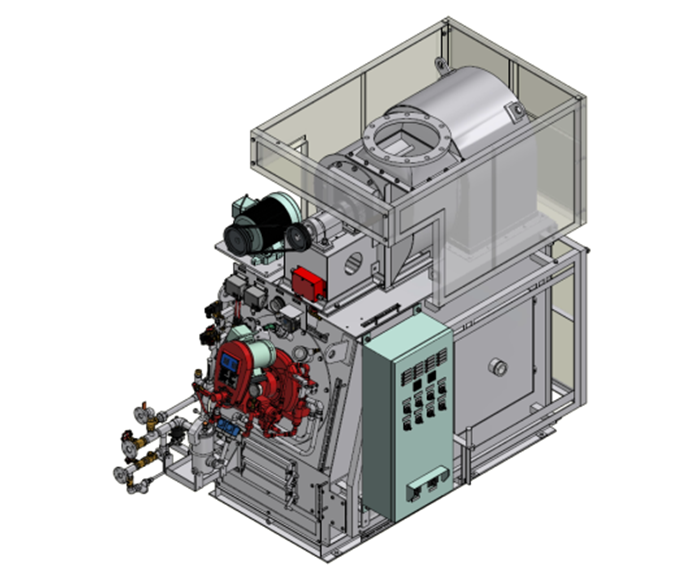

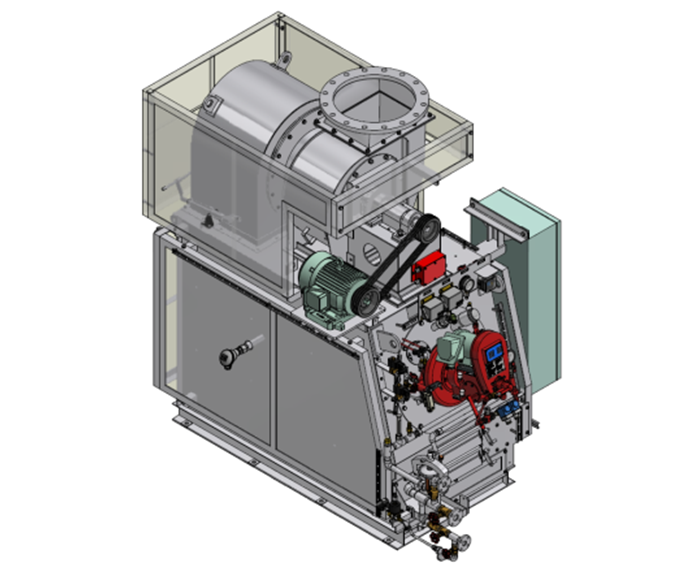

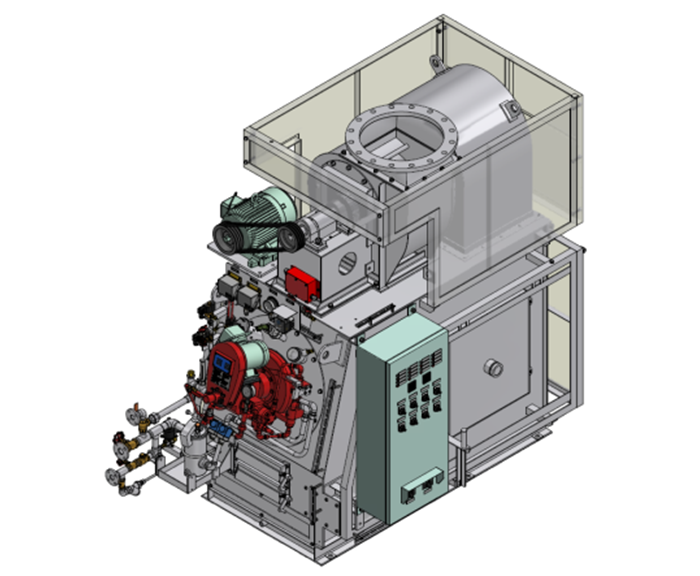

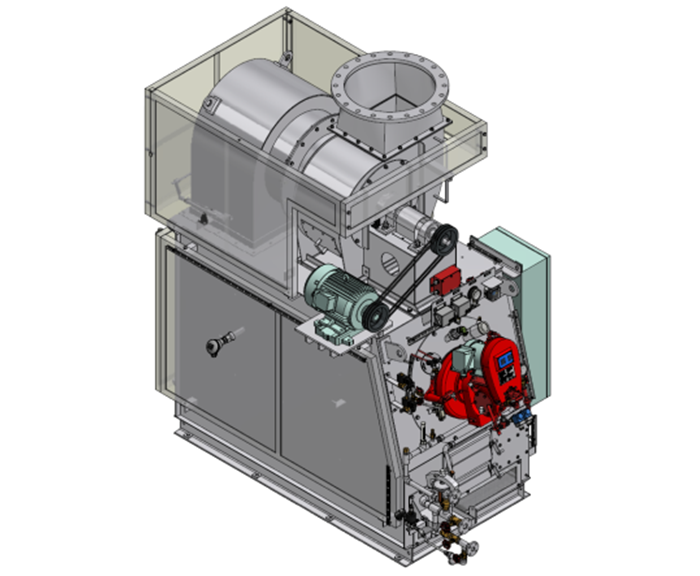

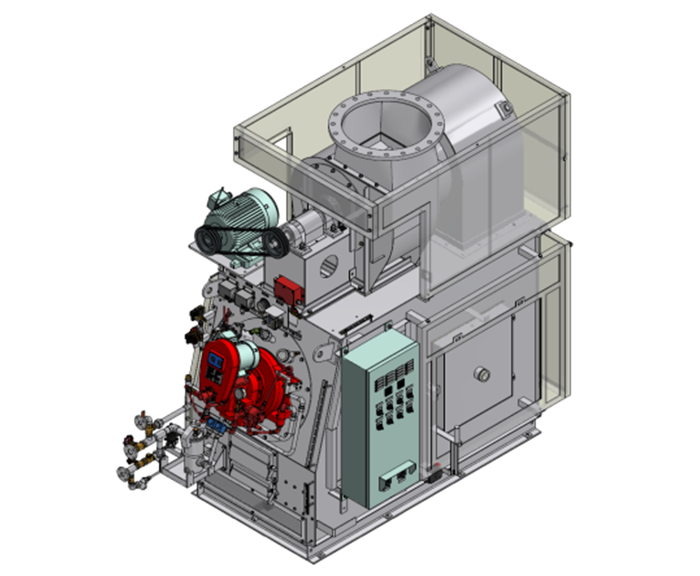

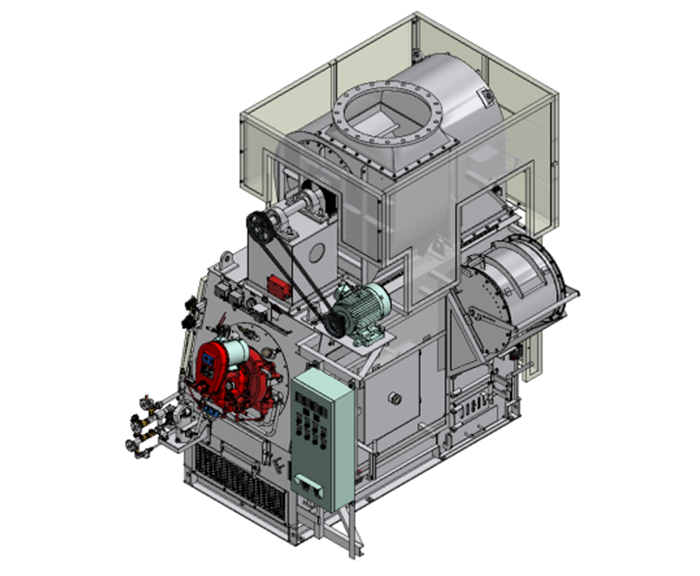

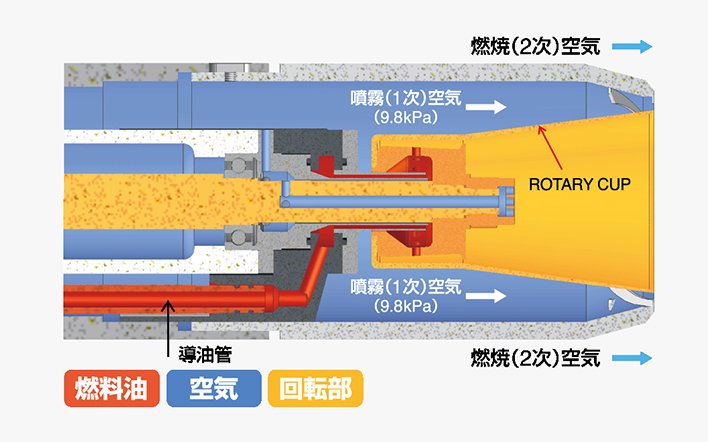

01Sunflame's Core Technology

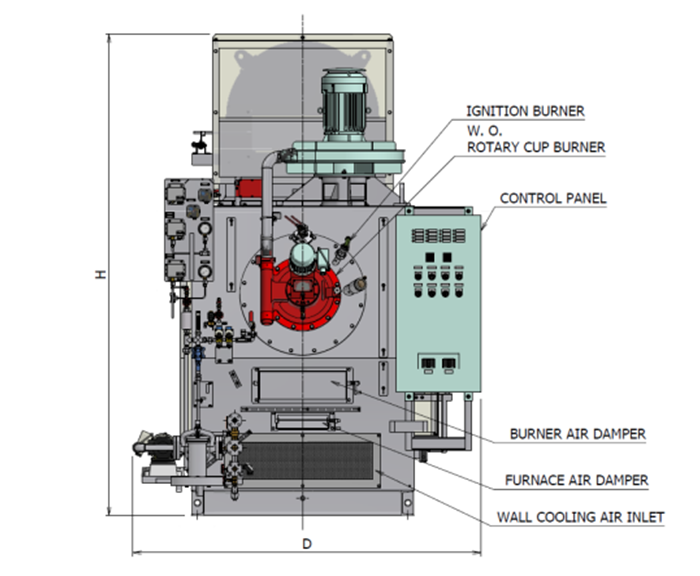

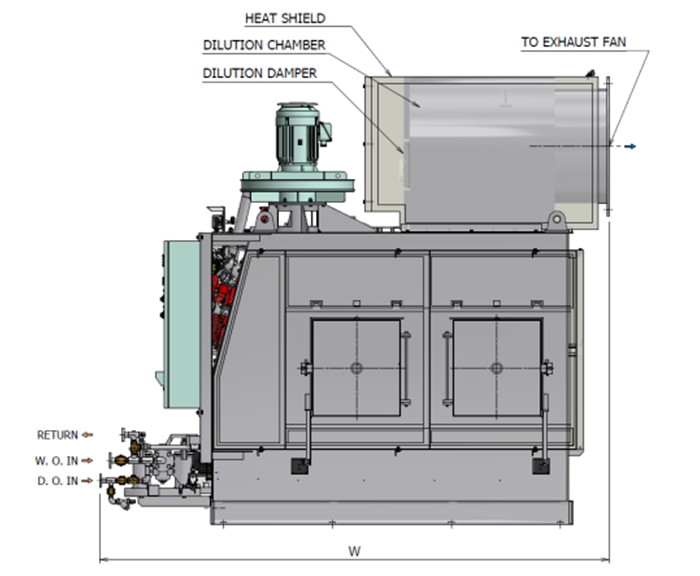

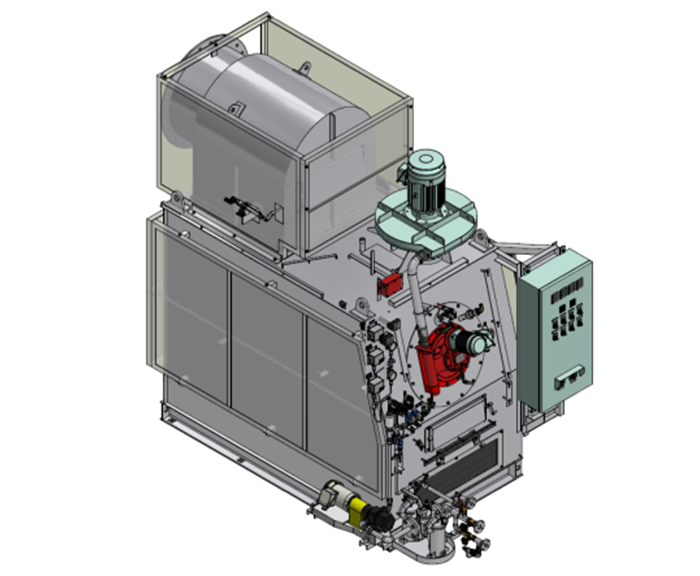

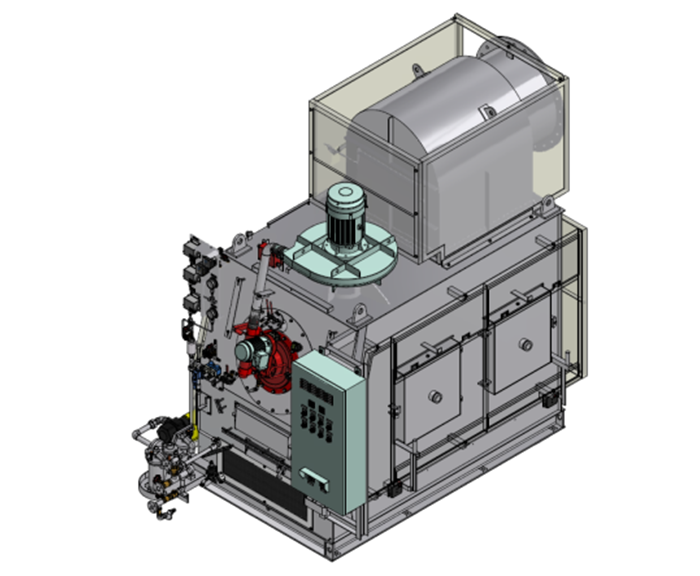

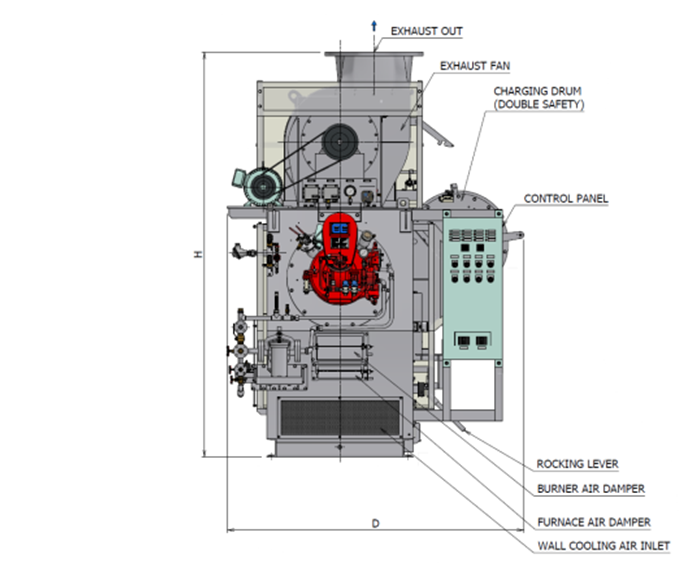

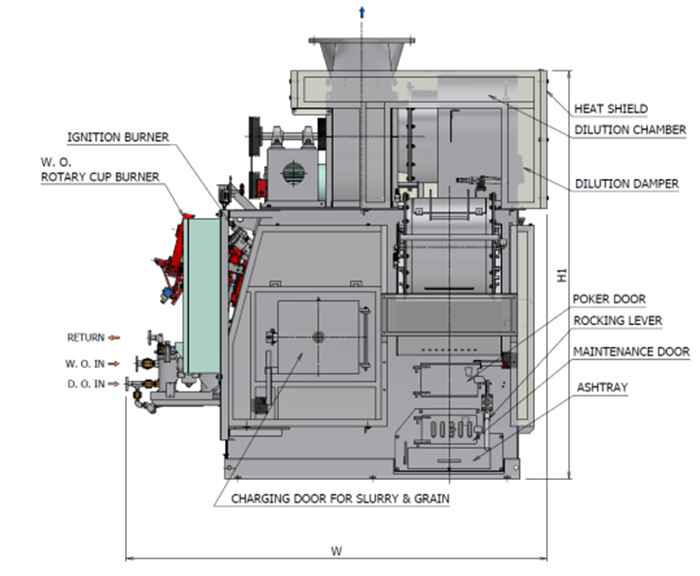

Rotary cup burner installed on all models; ideal for atomizing low quality fuels with high viscosity.

-

02Stable Continuous Combustion

Prevents flame failure induced by nozzle clogging; use of centrifugal force and air atomizes waste oil efficiently.

-

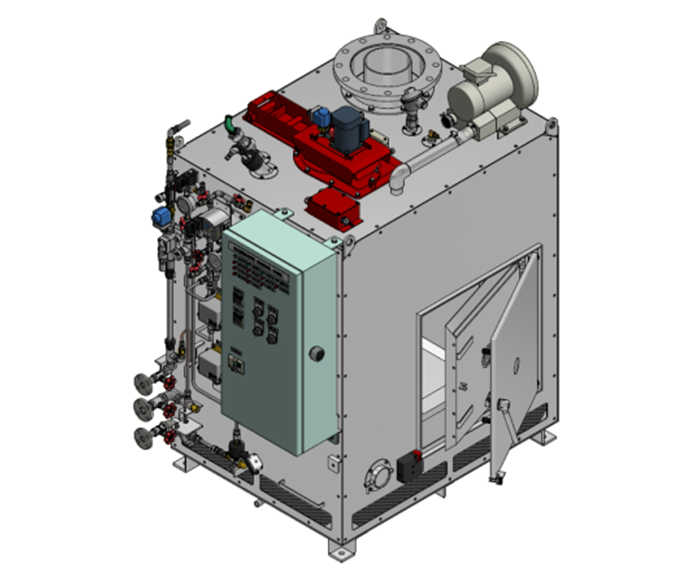

03Easy Maintenance

Hassle-free maintenance and cleaning; simply open the hinged door to access burner.

-

04Safety with Low Oil Pressure

Low pressure within oil piping; prevents oil leakage and pump consumption during operation.

05Specialized Refractory

-

Material

A refractory generally varies in finishing quality as it is often affected by temperature and humidity. However, Sunflame's refractories maintain a stable quality year-round by adjusting the ingredients depending on climate.

-

Methodology

We maintain material strength by standardizing the solidification speed, and stabilize quality by strictly managing water content and construction procedures.

-

Finish

Our incinerators are dry-operated for 4 hours as a finishing process to evaporate the moisture remaining inside the refractory. This process prevents damage from sudden increase in temperature during its initial operation and helps maintain product quality during its lifespan.

Product Line-Up

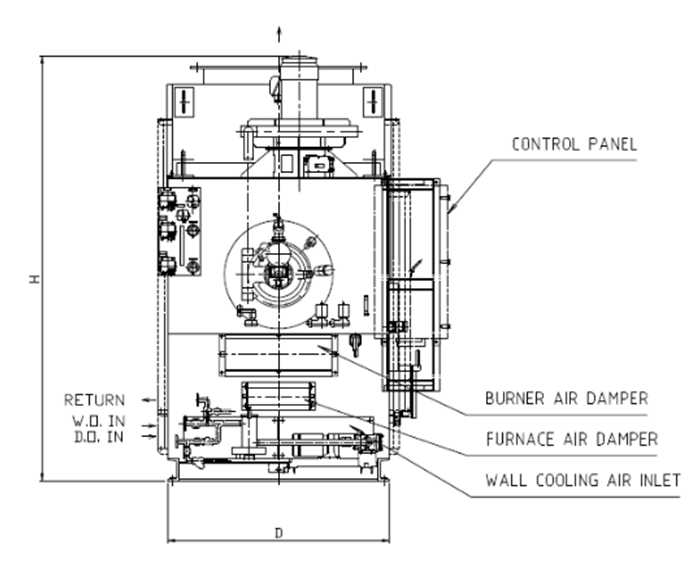

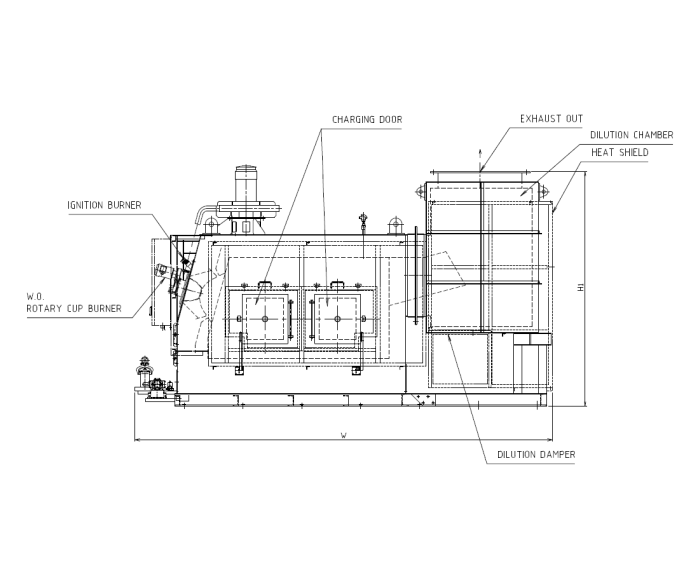

- OSV2-190S

- OSV-240SAI

- OSV-360SAI

- OSV-600SAI

- OSV-900SAI

- OSV-1200SAI

- OSV-1500SAI

- OSV-2400SAI

- OSG-360SDA

- OSG-600SDA

- OSG-900SDA

- OSG-1200SDA

- OSG-1500SDA

| Combustion Capacity | 684 MJ/h |

|---|---|

| 163,000 kcal/h | |

| Waste Oil Capacity | 19 kg/h |

| Solid Waste Capacity | 5 kg/h |

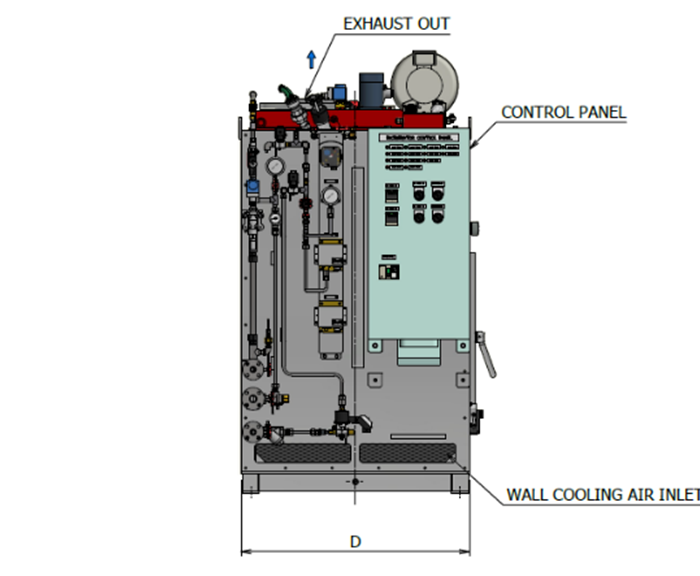

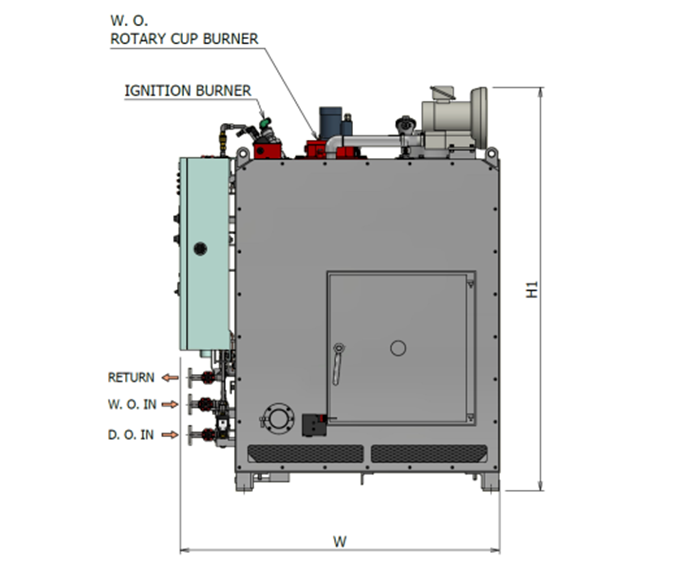

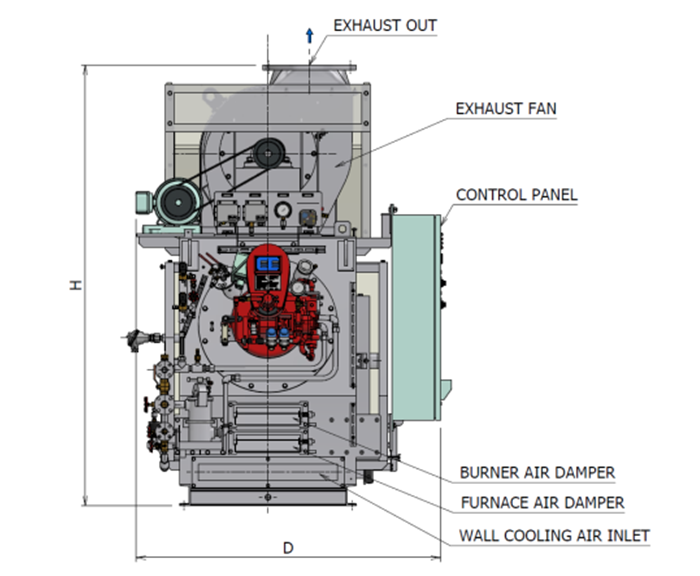

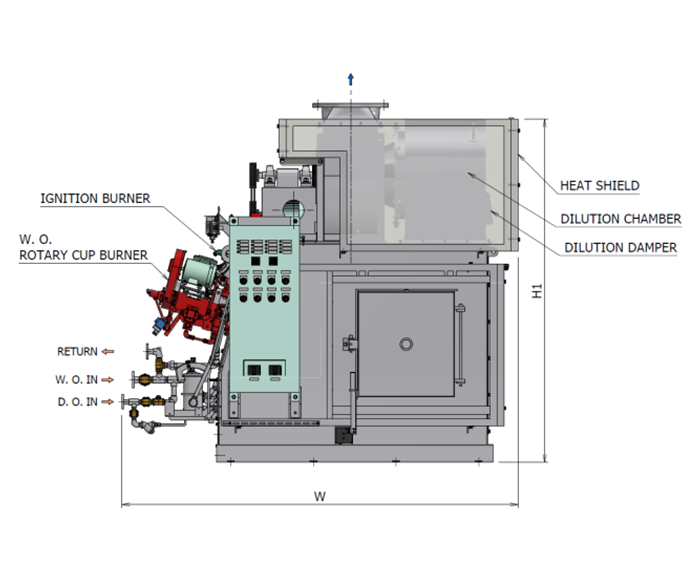

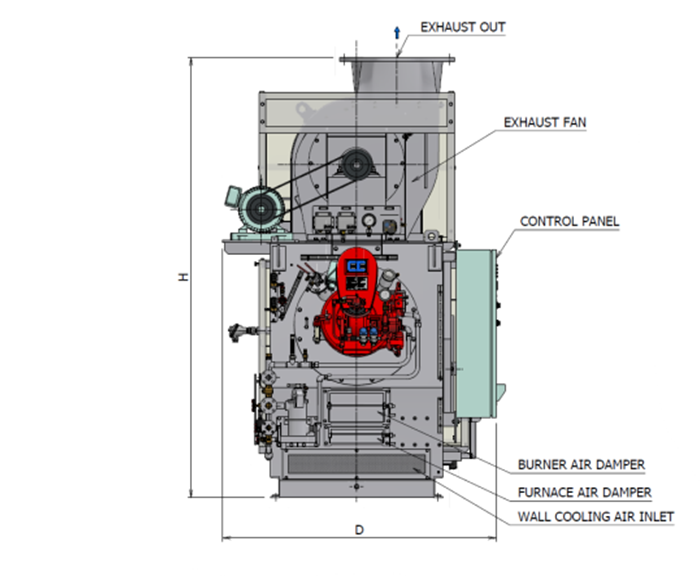

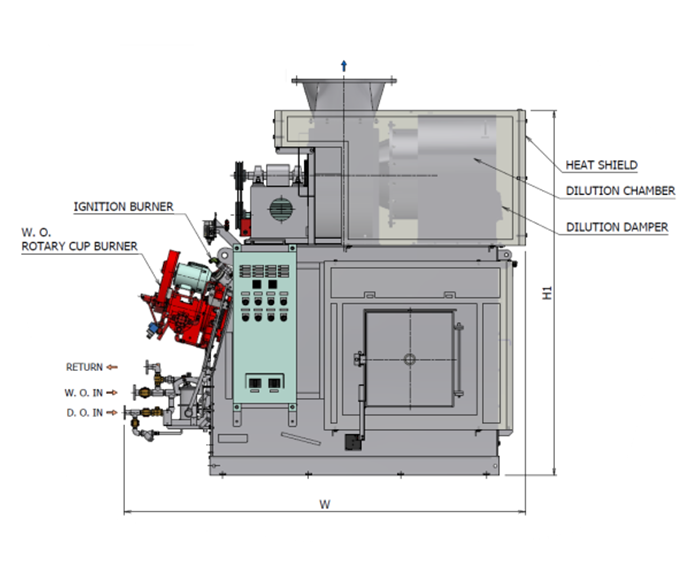

| Size W x D x H(H1) (mm) |

1,314 × 860 × (1,658)mm

*Excluding Exhaust Fan |

| Exh. Gas Duct Diameter(JIS 5K) | 250A |

| Weight(≒kg) | 1,400kg |

| Ship Type(Examples) | Coastal Cargo Carrier |

| Combustion Capacity | 860 MJ/h |

|---|---|

| 210,000 kcal/h | |

| Waste Oil Capacity | 26 kg/h |

| Solid Waste Capacity | 20 kg/h |

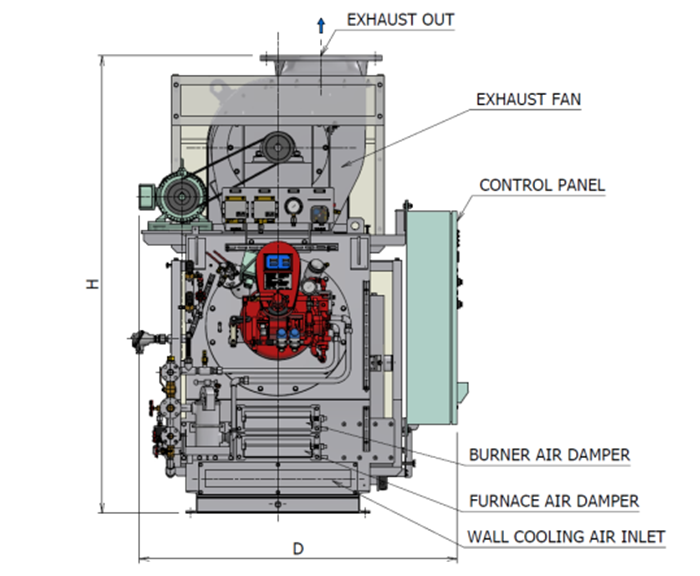

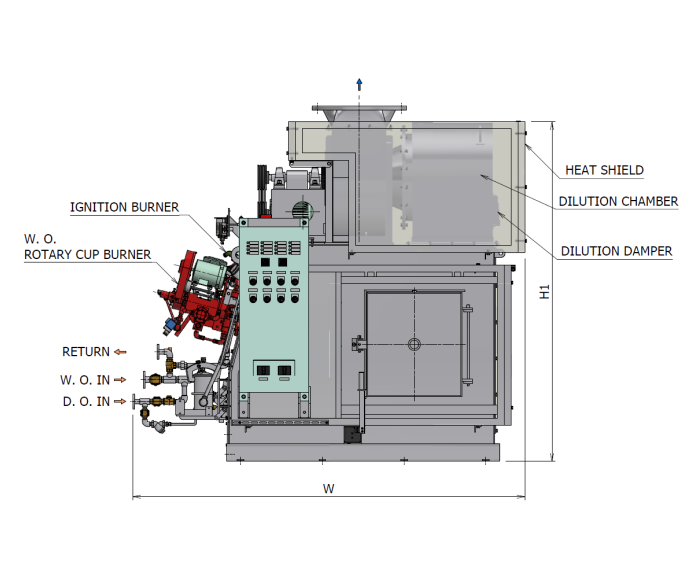

| Size W x D x H(H1) (mm) |

2,255 × 1,410 × 2,042 (1,952)mm |

| Exh. Gas Duct Diameter(JIS 5K) | 300A |

| Weight(≒kg) | 2,350kg |

| Ship Type (Examples) | Bulk Carrier |

| Combustion Capacity | 1,300 MJ/h |

|---|---|

| 310,000 kcal/h | |

| Waste Oil Capacity | 38 kg/h |

| Solid Waste Capacity | 30 kg/h |

| Size W x D x H(H1) (mm) |

2,255 × 1,425 × 2,042 (1,952)mm |

| Exh. Gas Duct Diameter(JIS 5K) | 400A |

| Weight(≒kg) | 2,400kg |

| Ship Type (Examples) | Bulk Carrier |

| Combustion Capacity | 2,160 MJ/h |

|---|---|

| 516,000 kcal/h | |

| Waste Oil Capacity | 64 kg/h |

| Solid Waste Capacity | 50 kg/h |

| Size W x D x H(H1) (mm) |

2,525 × 1,580 × 2,496 (2,297)mm |

| Exh. Gas Duct Diameter(JIS 5K) | 500A |

| Weight(≒kg) | 3,100kg |

| Ship Type (Examples) | Bulk Carrier |

| Combustion Capacity | 3,240 MJ/h |

|---|---|

| 770,000 kcal/h | |

| Waste Oil Capacity | 97 kg/h |

| Solid Waste Capacity | 75 kg/h |

| Size W x D x H(H1) (mm) |

2,925 × 1,944 × 2,956 (2,711)mm |

| Exh. Gas Duct Diameter(JIS 5K) | 600A |

| Weight(≒kg) | 4,700kg |

| Ship Type (Examples) | PCC, VLCC, VLGC, Container |

| Combustion Capacity | 4,320 MJ/h |

|---|---|

| 1,030,000 kcal/h | |

| Waste Oil Capacity | 129 kg/h |

| Solid Waste Capacity | 100 kg/h |

| Size W x D x H(H1) (mm) |

2,890 × 2,120 × (2,791)mm

*Excluding Exhaust Fan |

| Exh. Gas Duct Diameter(JIS 5K) | 700A |

| Weight(≒kg) | 6,100kg |

| Ship Type (Examples) | VLCC, Container |

| Combustion Capacity | 5,400 MJ/h |

|---|---|

| 1,290,000 kcal/h | |

| Waste Oil Capacity | 161 kg/h |

| Solid Waste Capacity | 125 kg/h |

| Size W x D x H(H1) (mm) |

3,150 × 2,120 × (2,791)mm

*Excluding Exhaust Fan |

| Exh. Gas Duct Diameter(JIS 5K) | 800A |

| Weight(≒kg) | 6,600kg |

| Ship Type (Examples) | Container |

| Combustion Capacity | 8,640 MJ/h |

|---|---|

| 2,060,000 kcal/h | |

| Waste Oil Capacity | 258 kg/h |

| Solid Waste Capacity | 200 kg/h |

| Size W x D x H(H1) (mm) |

4,950 × 2,138 × 2,825mm |

| Exh. Gas Duct Diameter(JIS 5K) | 1000A |

| Weight(≒kg) | 8,900kg |

| Ship Type (Examples) | Container |

| Combustion Capacity | 1,300 MJ/h |

|---|---|

| 310,000 kcal/h | |

| Waste Oil Capacity | 38 kg/h |

| Solid Waste Capacity | 48 kg/h |

| Size W x D x H(H1) (mm) |

2,525 × 1,871 × 2,459 (2,415)mm |

| Exh. Gas Duct Diameter(JIS 5K) | 400A |

| Weight(≒kg) | 3,750kg |

| Ship Type (Examples) | Bulk Carrier |

| Combustion Capacity | 2,160 MJ/h |

|---|---|

| 516,000 kcal/h | |

| Waste Oil Capacity | 64 kg/h |

| Solid Waste Capacity | 80 kg/h |

| Size W x D x H(H1) (mm) |

2,525 × 2,036 × 2,714 (2,515)mm |

| Exh. Gas Duct Diameter(JIS 5K) | 500A |

| Weight(≒kg) | 3,800kg |

| Ship Type (Examples) | Bulk Carrier |

| Combustion Capacity | 3,240 MJ/h |

|---|---|

| 770,000 kcal/h | |

| Waste Oil Capacity | 97 kg/h |

| Solid Waste Capacity | 120 kg/h |

| Size W x D x H(H1) (mm) |

2,918 × 1,936 × 3,060 (2,900)mm |

| Exh. Gas Duct Diameter(JIS 5K) | 600A |

| Weight(≒kg) | 5,600kg |

| Ship Type (Examples) | PCC, Oil Tanker, Container |

| Combustion Capacity | 4,320 MJ/h |

|---|---|

| 1,030,000 kcal/h | |

| Waste Oil Capacity | 129 kg/h |

| Solid Waste Capacity | 160 kg/h |

| Size W x D x H(H1) (mm) |

2,890 × 2,380 × (2,791)mm

*Excluding Exhaust Fan |

| Exh. Gas Duct Diameter(JIS 5K) | 700A |

| Weight(≒kg) | 7,000kg |

| Ship Type (Examples) | VLCC, Container |

| Combustion Capacity | 5,400 MJ/h |

|---|---|

| 1,290,000 kcal/h | |

| Waste Oil Capacity | 161 kg/h |

| Solid Waste Capacity | 200 kg/h |

| Size W x D x H(H1) (mm) |

3,150 × 2,380 × (2,791)mm

*Excluding Exhaust Fan |

| Exh. Gas Duct Diameter(JIS 5K) | 800A |

| Weight(≒kg) | 7,500kg |

| Ship Type (Examples) | Container |

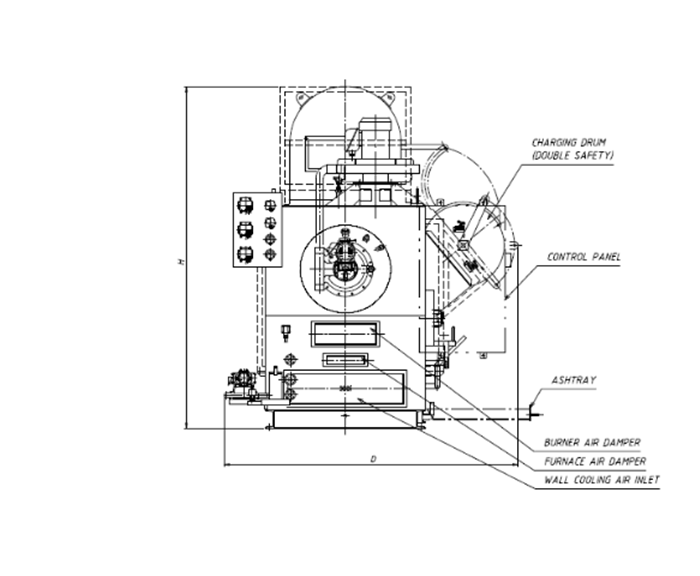

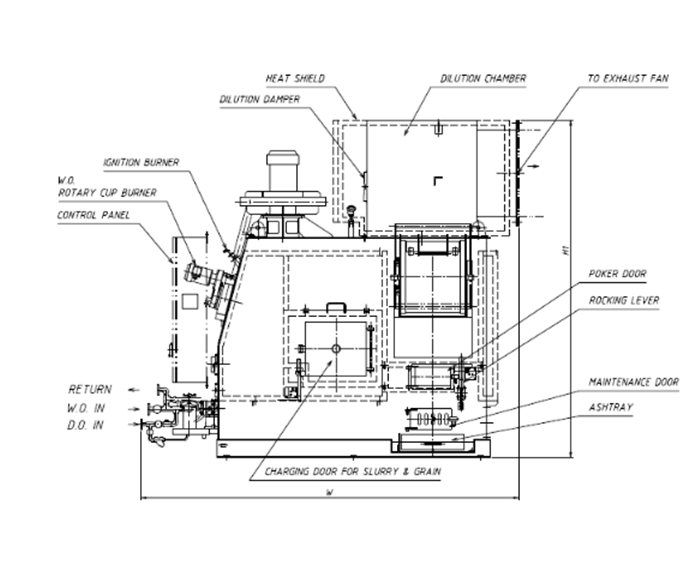

Optional Equipments

-

Garbage Feeder

Allows for waste disposal during operation by replacing the existing single door with a garbage feeder. Also increases waste disposal volume and facilitates Garbage Record Book entry.

-

Ceramic Board Refractory

Can be replaced in 10 mins per board; consistent finishing quality regardless of operator.