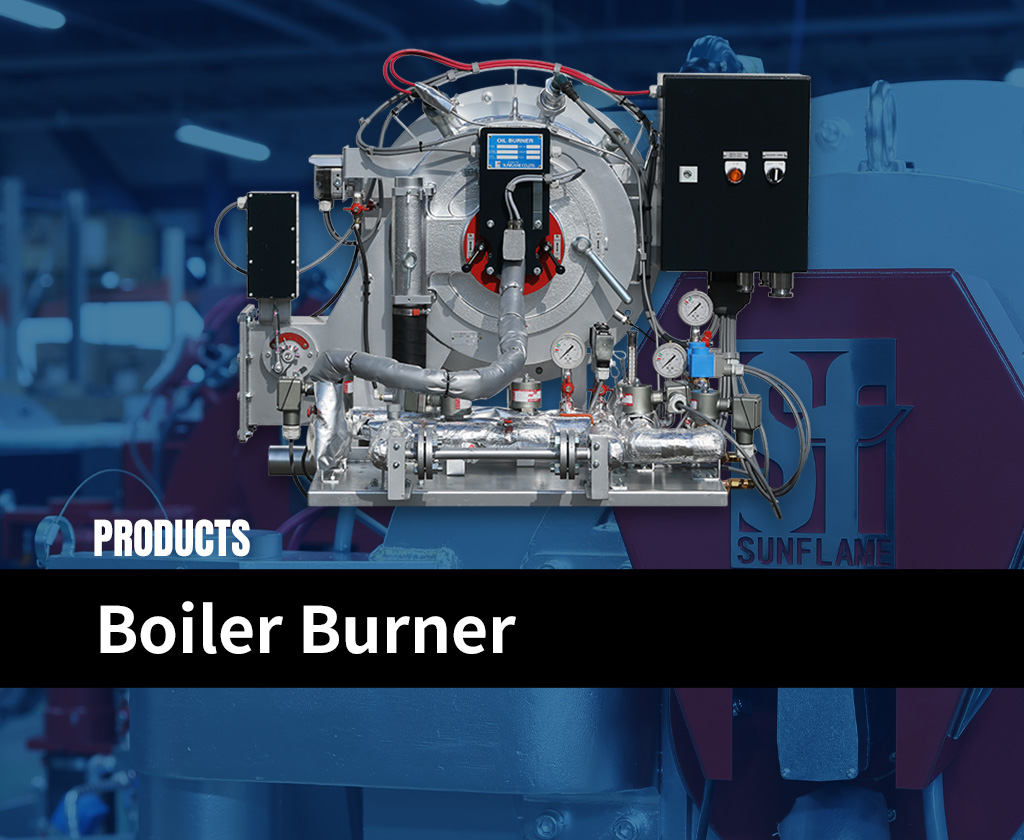

PRODUCTS

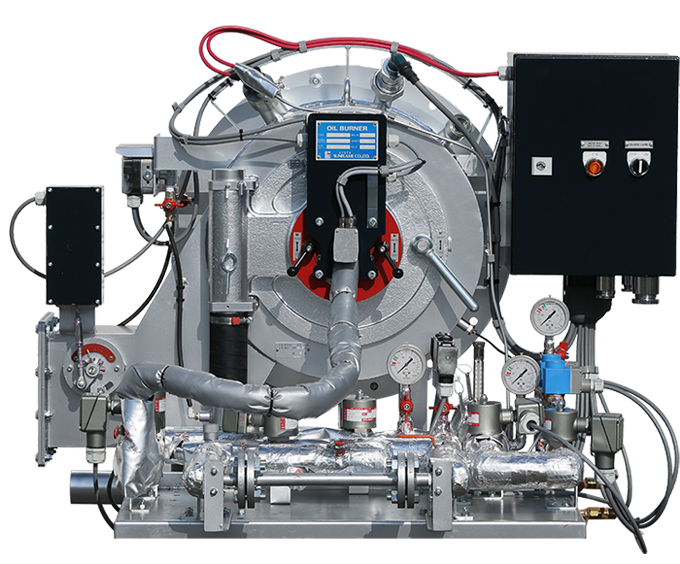

Burner for Aux. Boiler

Safe and efficient combustion through years of innovation

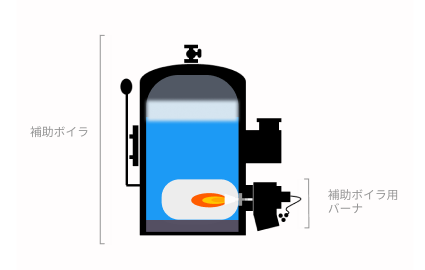

What is an Auxiliary Boiler Burner?

An auxiliary boiler burner is an apparatus used to produce flame for heating auxiliary boilers. It is an essential equipment used by vessels at anchorage and during voyage.

The auxiliary boiler uses the flame from the burner as a heat source to produce steam. The steam is used to heat fuel to proper temperature, to adjust air conditioning and water temperature, to clean cargo tanks, and to run cargo pumps on oil tankers.

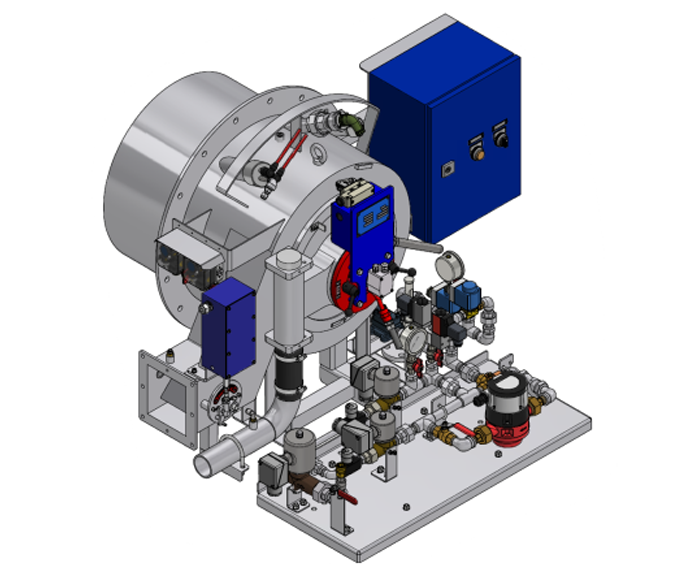

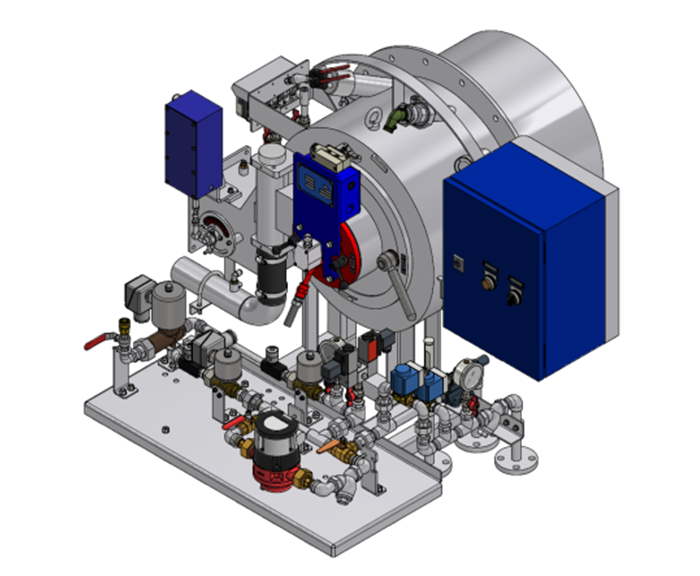

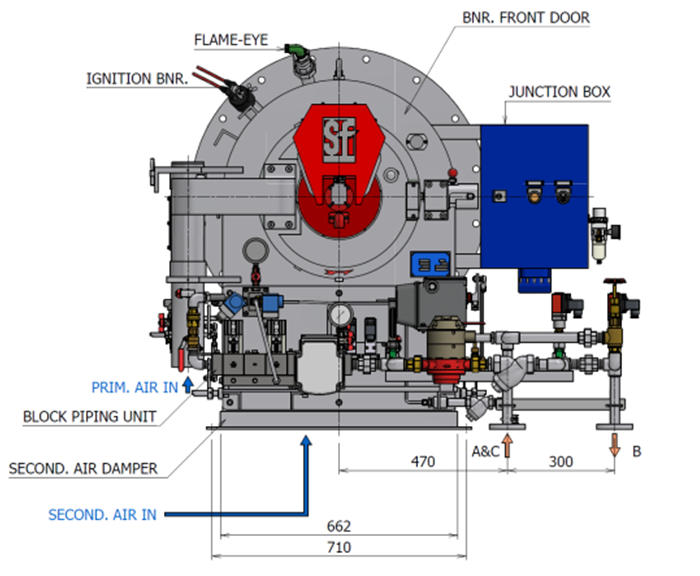

The "rotary cup burner" is the core technology of our Auxiliary Boiler Burner; its stable combustion is made possible with the joint development of our hardware and software. By optimizing the performance of our burners, we offer the perfect solution for your vessel's needs.

Advantages

-

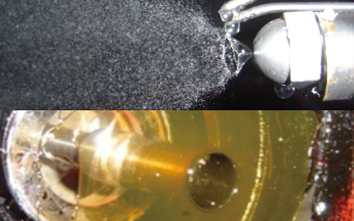

01Stable Combustion

The rotary cup burner is able to maintain fine fuel atomization for a wide range of fuel conditions and characteristics. Stable combustion is available at a wide range of flame size because essential factors such as fuel volume, atomizing air volume, combustion air volume and rotary cup speed can be controlled individually.

-

02Low Oil Pressure

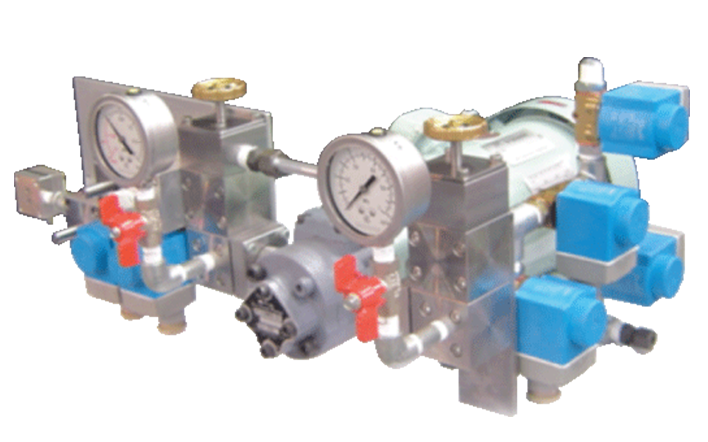

Since the fuel pressure for atomization is only 0.3-0.5MPa, it prevents scattering in case of fuel leakage and is safe to use. It also minimizes equipment wear and the need for parts replacement.

-

03Less Clogging

The rotary cup burner is clog-free as it does not use the tiny hole of a nozzle tip to atomize fuel.

-

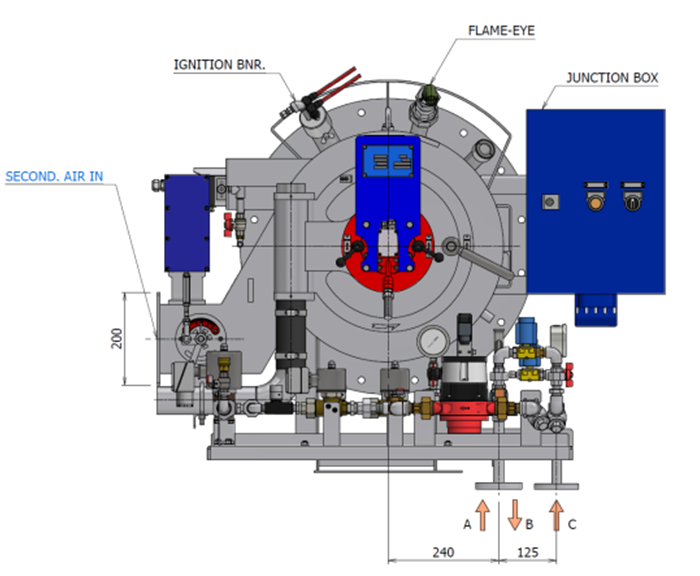

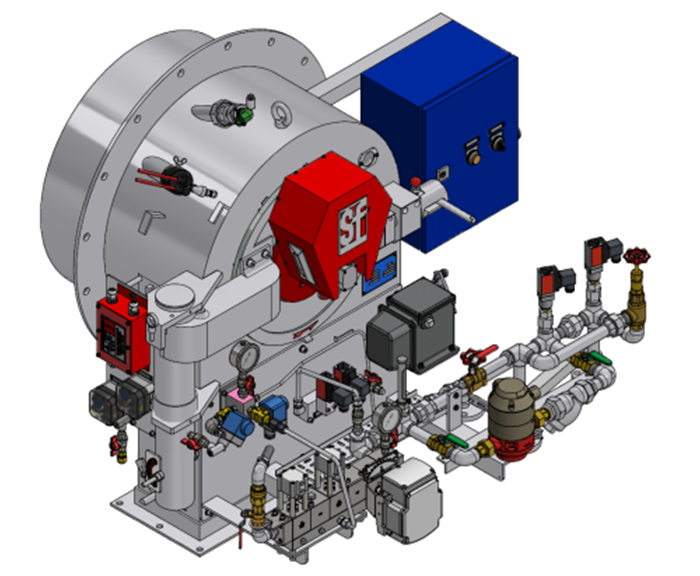

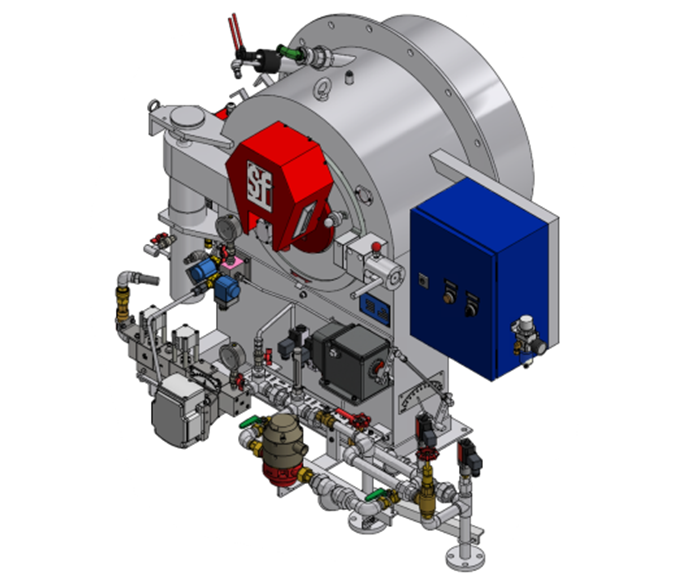

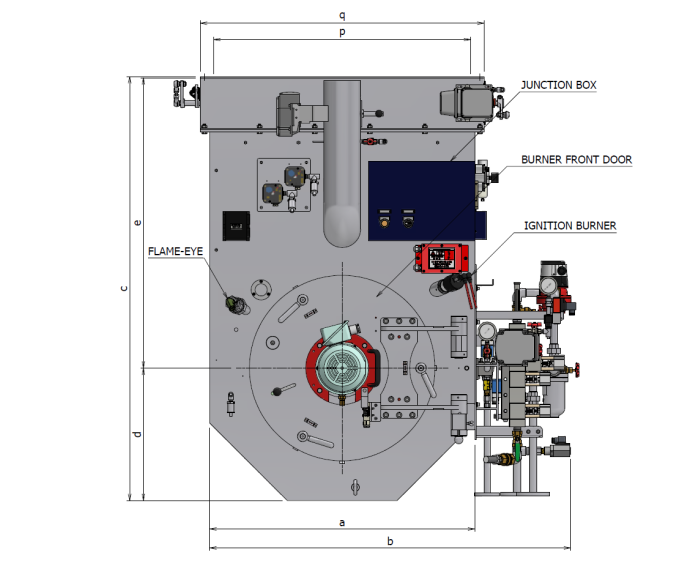

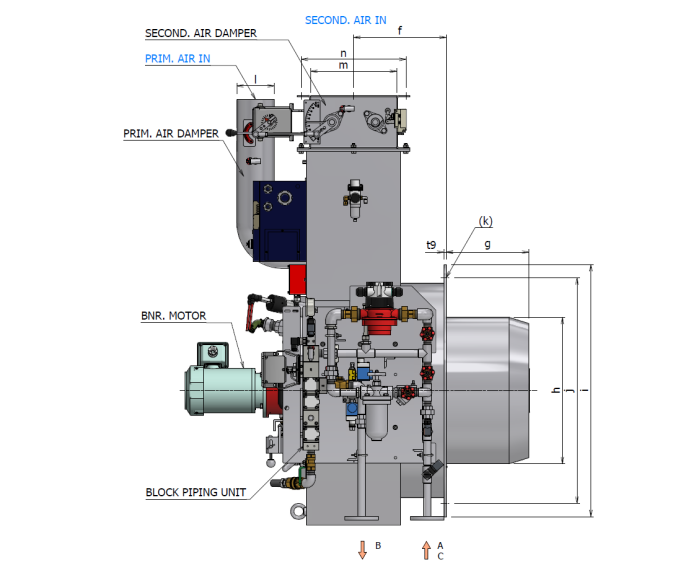

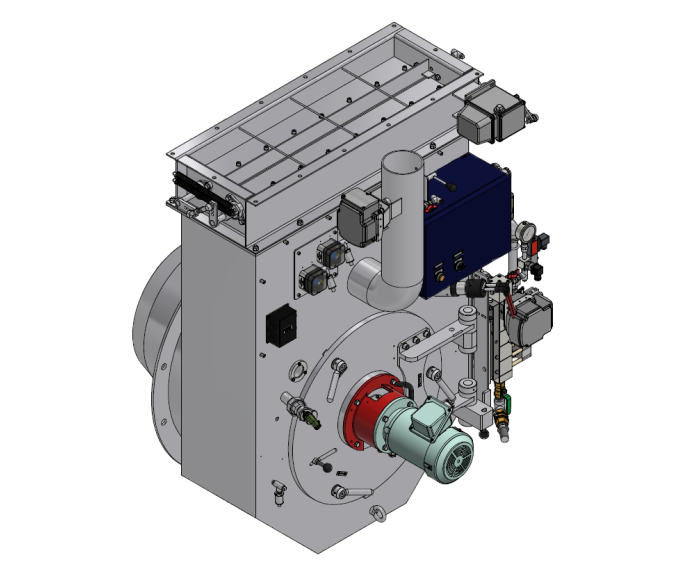

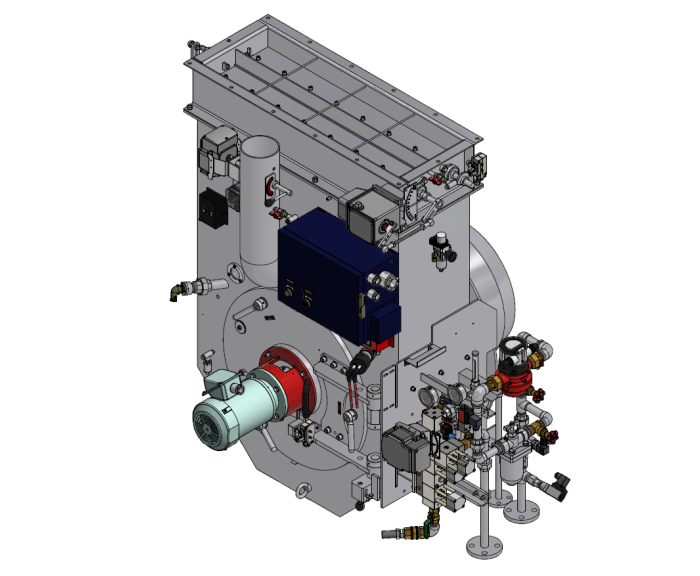

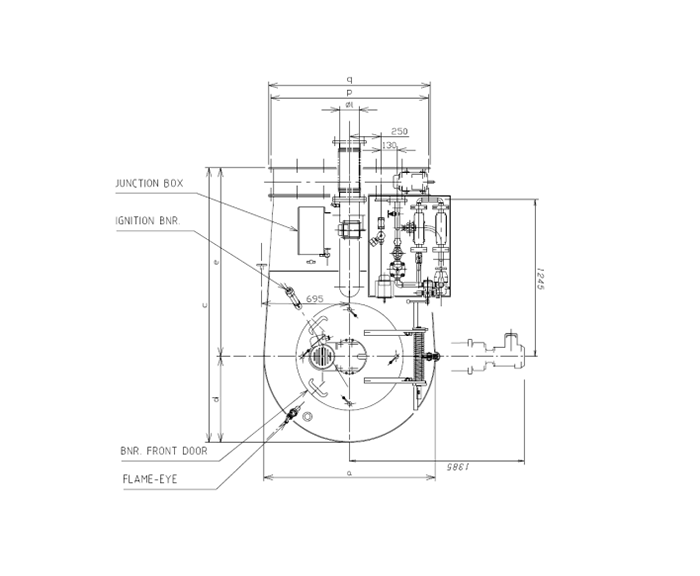

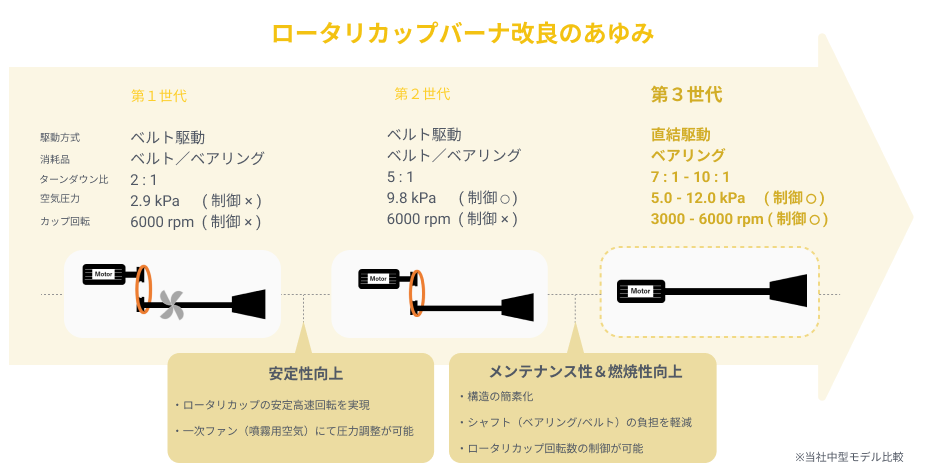

04Simple Structure

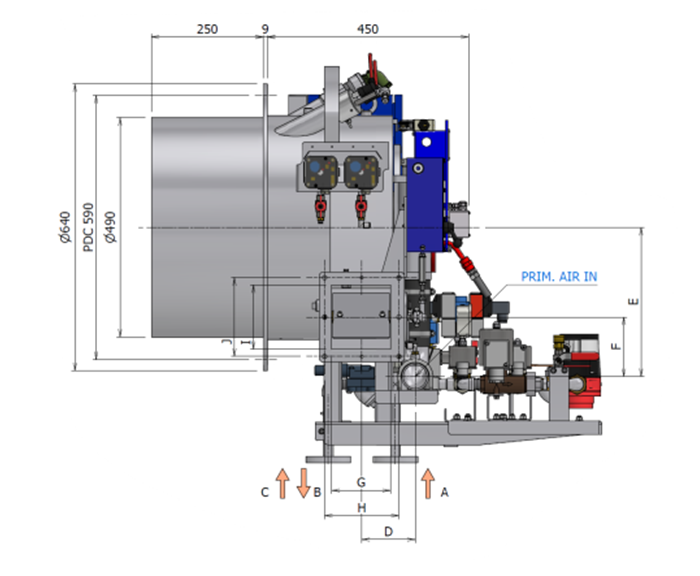

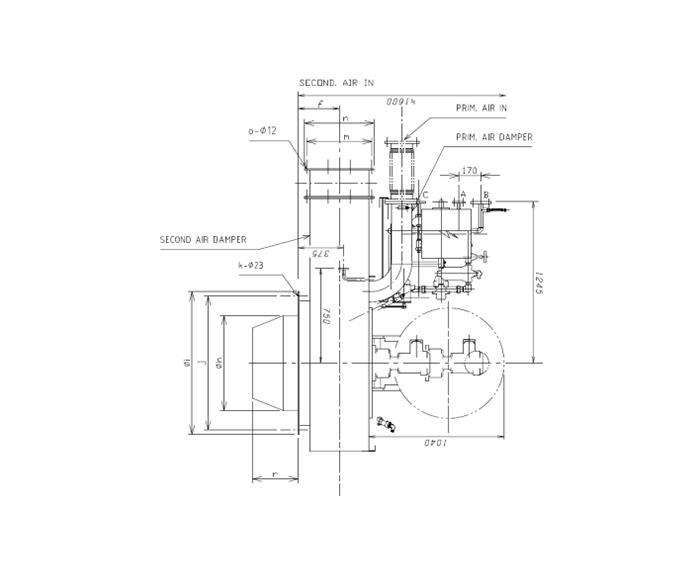

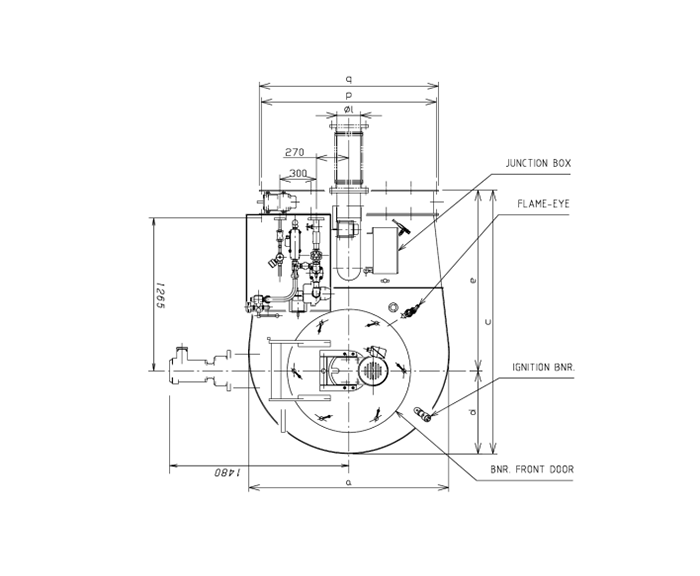

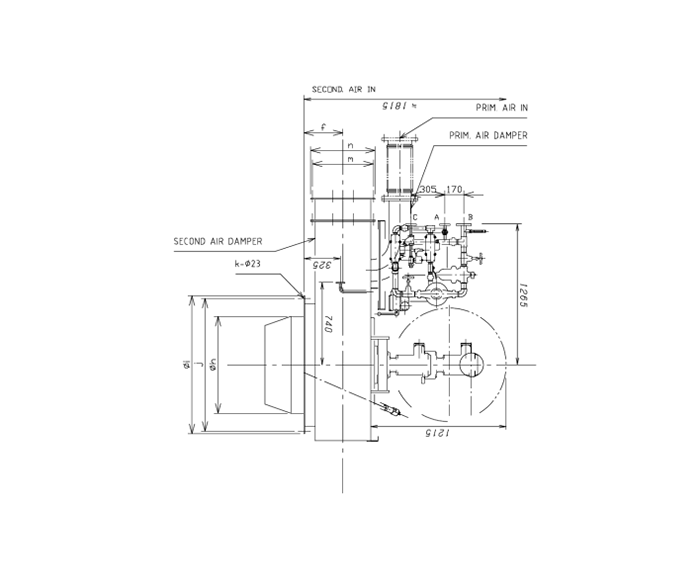

The motor is attached directly to the shaft, and the primary air for atomization is installed separately. This structure allows for fewer parts and less stress onto the shaft as well as finer combustion control. The motor is attached directly to the shaft and is separate from the primary air fan for atomization. This structure minimizes stress onto the shaft and the number of parts, and allows for finer combustion control.

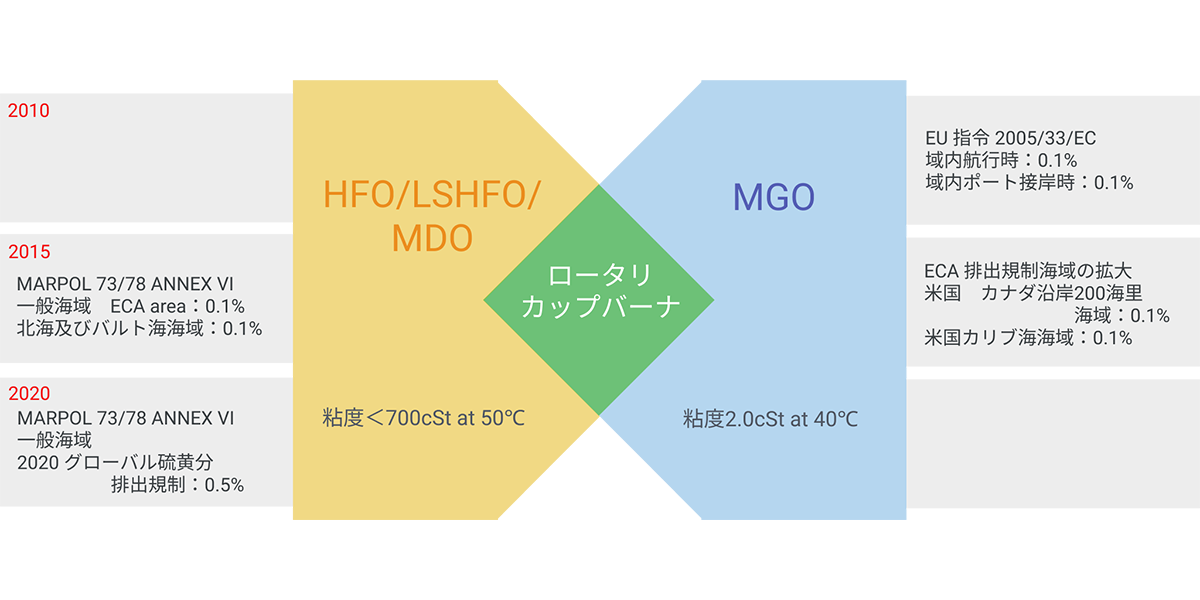

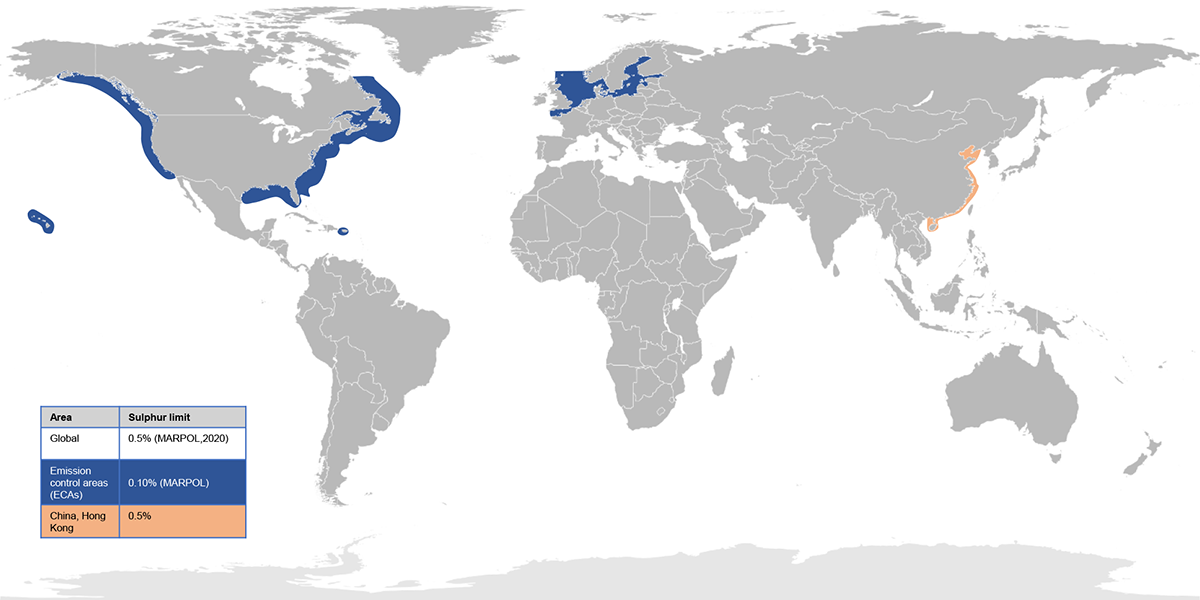

05Compatibility with Various Fuels

- Rotary cup burner supports fuel viscosity between 1.5 cSt to 700 cSt and is able to switch between fuels during operation

- No need to change nozzles, pumps or other hardware settings when switching between fuels

- Safely switch between HFO and MGO fuels

06Simple Maintenance

- Main burner is attached to hinge door for easy maintenance

- Reduced total weight and number of parts

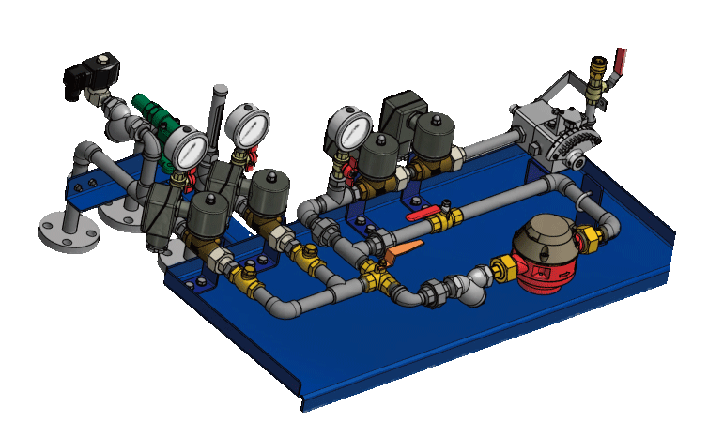

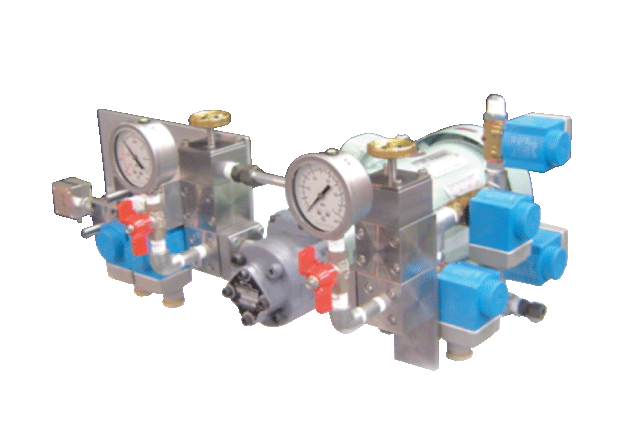

- For SDR-350 to SDR-1500, the main valve and fuel control valves are integrated into a block unit, reducing consumable parts and maintenance work

07Low Fuel Consumption

-

Wide Turndown Ratio

It optimizes combustion volume according to steam consumption demand. The amount of fuel can be adjusted to maximize heat exchange for a wide range of steam consumption demand.

-

Combustion Air Volume Optimization

Optimizing combustion air volume reduces heat loss during combustion, leading to fuel efficiency.

-

Less Fuel Consumption

Improve fuel efficiency even further with the Emulsion Combustion System, available as an optional upgrade.

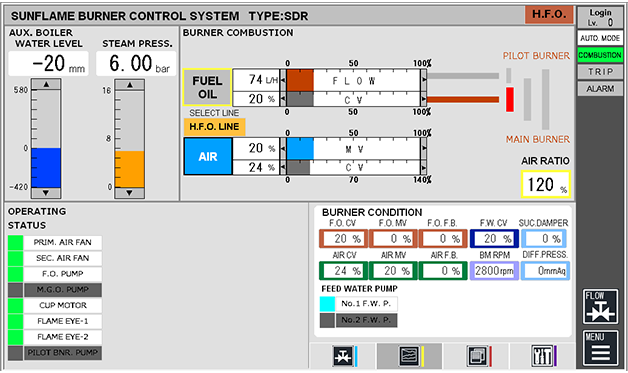

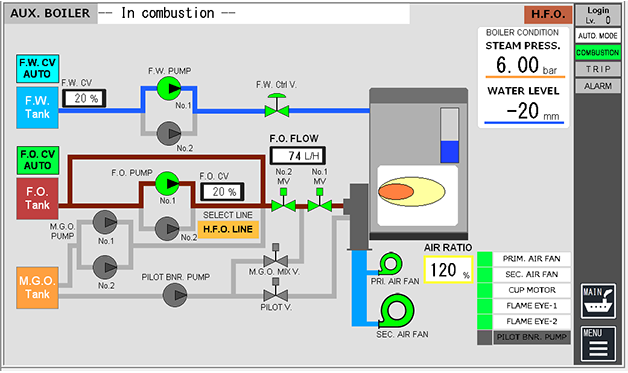

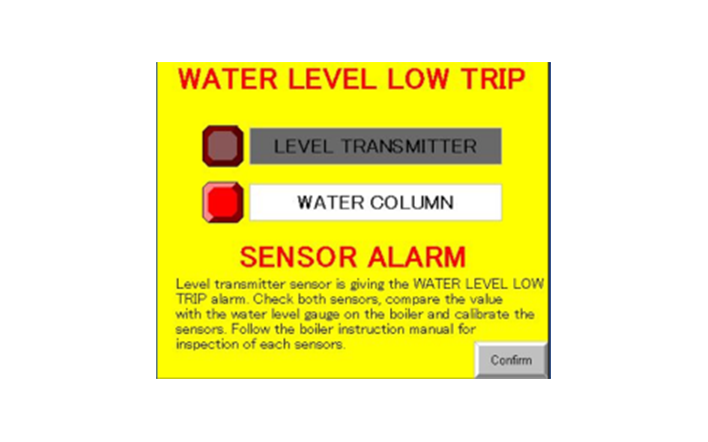

08Control Panel

A graphic touchscreen is equipped onto the control panel to improve usability.

In case of machine troubles, the source can be tracked using the data logger function.

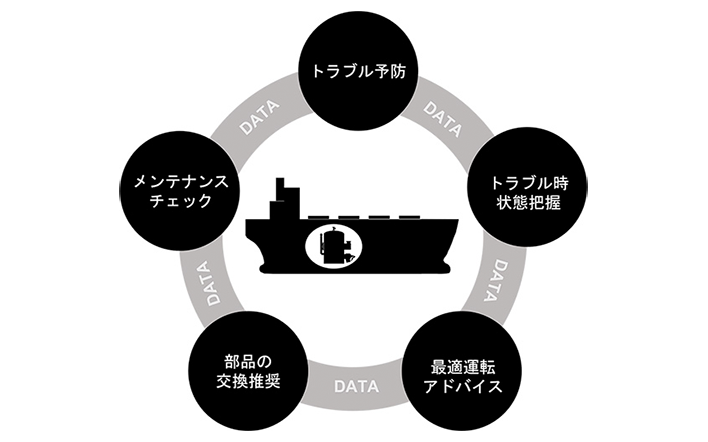

Accurate Remote Advice

- We will check the critical condition and offer operation advice based on details on the control panel screen.

- The data logger function can also be used to check the machine condition before the trouble.

Troubleshooting Display

- Troubleshooting procedures will be displayed on the screen in case of machine troubles.

Product Line-Up

- SDR-1

- SDR-1.5

- SDR-2

- SDR-2.5

- SDR-350

- SDR-500

- SDR-700

- SDR-1000

- SDR-1500

- R-25

- R-40

| Combustion Capacity | 45-100 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.15 MPa |

| Automatic Control System | ON/OFF Control |

| Cup Drive System | Motor Direct Drive System |

| Weight(≒kg) | 230 kg |

| Boiler Capacity | ~1.2t |

| Recommended Vessel Type | Bulk Carrier |

| Combustion Capacity | 50-150 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.3 MPa |

| Automatic Control System | ON/OFF Control |

| Cup Drive System | Motor Direct Drive System |

| Weight(≒kg) | 230 kg |

| Boiler Capacity | 1.2~2t |

| Recommended Vessel Type | Container, PCC, VLGC |

| Combustion Capacity | 50-200 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.3 MPa |

| Automatic Control System | ON/OFF & HIGH/LOW Control |

| Cup Drive System | Motor Direct Drive System |

| Weight(≒kg) | 230 kg |

| Coiler Capacity | 2~2.5t |

| Recommended Vessel Type | Container, PCC |

| Combustion Capacity | 50-250 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.3 MPa |

| Automatic Control System | ON/OFF & HIGH/LOW Control |

| Cup Drive System | Motor Direct Drive System |

| Weight(≒kg) | 230 kg |

| Boiler Capacity | 2.5~3t |

| Recommended Vessel Type | Container |

| Combustion Capacity | 50-350 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.3 MPa |

| Automatic Control System | ON/OFF & Proportional Control |

| Cup Drive System | Motor Direct Drive System |

| Weight(≒kg) | 600 kg |

| Boiler Capacity | 3~4.5t |

| Recommended Vessel Type | Container |

| Combustion Capacity | 50-500 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.3 MPa |

| Automatic Control System | ON/OFF & Proportional Control |

| Cup Drive System | Motor Direct Drive System |

| Weight(≒kg) | 600 kg |

| Boiler Capacity | 4.5~6t |

| Recommended Vessel Type | Container |

| Combustion Capacity | 70-700 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.3 MPa |

| Automatic Control System | ON/OFF & Proportional Control |

| Cup Drive System | Motor Direct Drive System |

| Weight(≒kg) | 600 kg |

| Boiler Capacity | 6~9t |

| Recommended Vessel Type | Passenger |

| Combustion Capacity | 100-1000 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.3 MPa |

| Automatic Control System | ON/OFF & Proportional Control |

| Cup Drive System | Motor Direct Drive System |

| Weight(≒kg) | 600 kg |

| Boiler Capacity | 9~12t |

| Recommended Vessel Type | Product/Chemical Tanker |

| Combustion Capacity | 150-1500 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.3 MPa |

| Automatic Control System | ON/OFF & Proportional Control |

| Cup Drive System | Motor Direct Drive System |

| Weight(≒kg) | 600 kg |

| Boiler Capacity | 12~20t |

| Recommended Vessel Type | Product/Chemical Tanker |

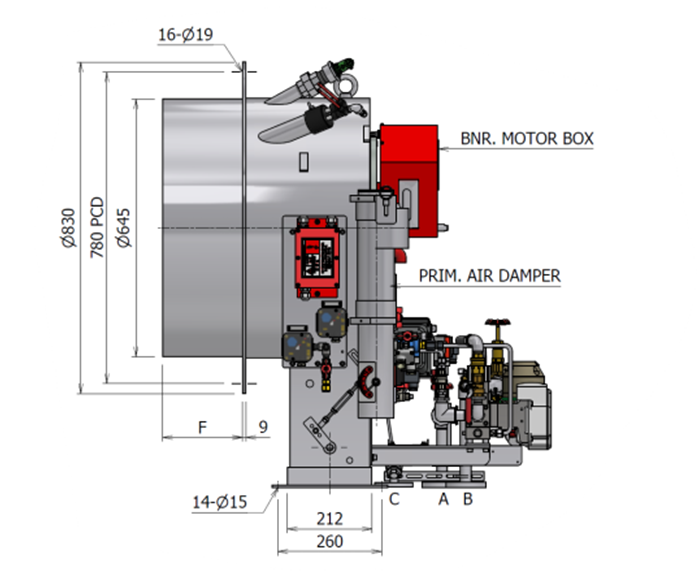

| Combustion Capacity | 250-2500 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.4 Mpa |

| Automatic Control System | ON/OFF & Proportional Control |

| Cup Drive System | Belt Drive System |

| Weight(≒kg) | 850 kg |

| Boiler Capacity | 20~35t |

| Recommended Vessel Type | Product Tanker, VLCC |

| Combustion Capacity | 400-4000 kg/h |

|---|---|

| Fuel Oil | Heavy Oil (Viscosity 700mm2/s at 50℃), MGO, DMO, Waste Oil |

| Fuel Oil Pressure | 0.4-0.5 Mpa |

| Automatic Control System | ON/OFF & Proportional Control |

| Cup Drive System | Belt Drive System |

| Weight(≒kg) | 1200 kg |

| Boiler Capacity | 35~50t |

| Recommended Vessel Type | VLCC |