AFTER-SALES SERVICE

- HOME

- After-Sales Service

We will take care of your products even after delivery.

Starting out as burner maintenance engineers, we pride ourselves on the quality of service we provide after sales. We provide full support in not only maintenance but also with product upgrades and operational performance analyses.

List of Services

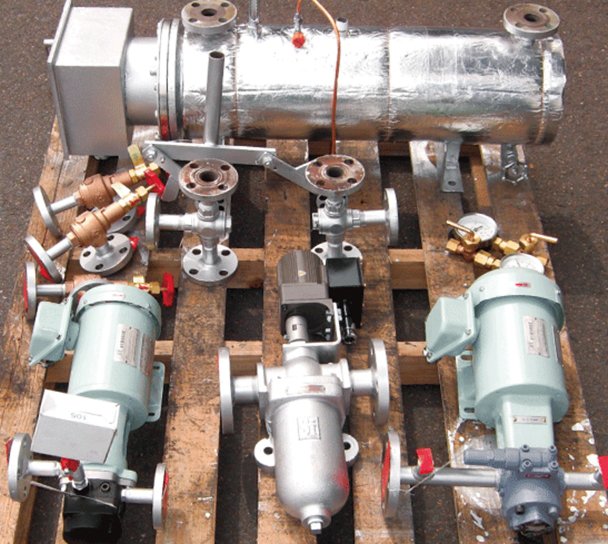

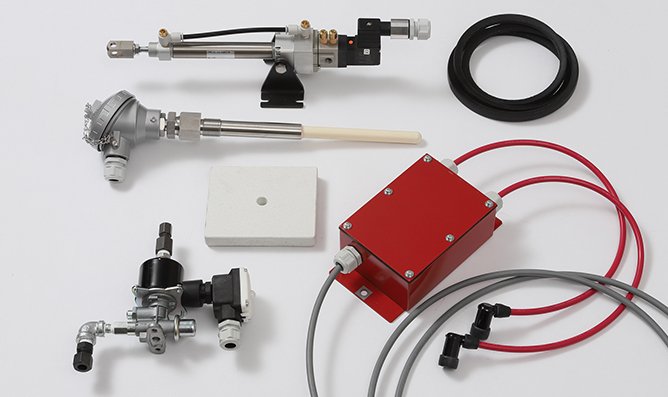

Spare Parts and

Accessories Sales

Periodic parts replacement is recommended to maintain product quality.

-

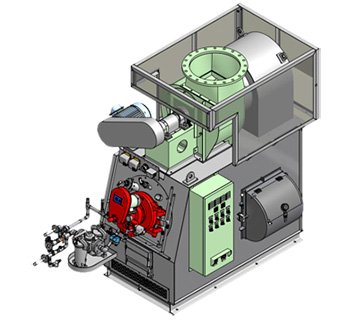

Burner Parts

-

Incinerator Parts

-

Electronic Components

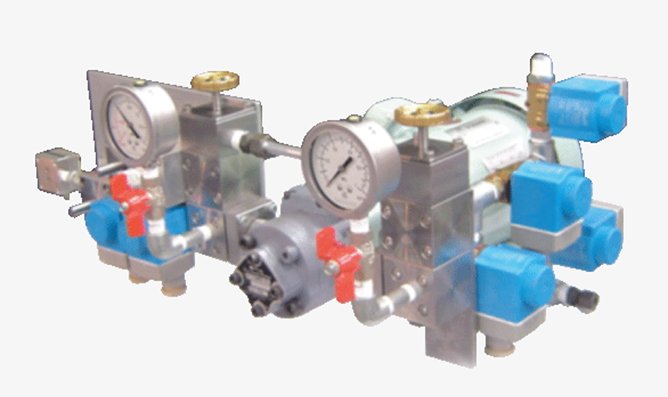

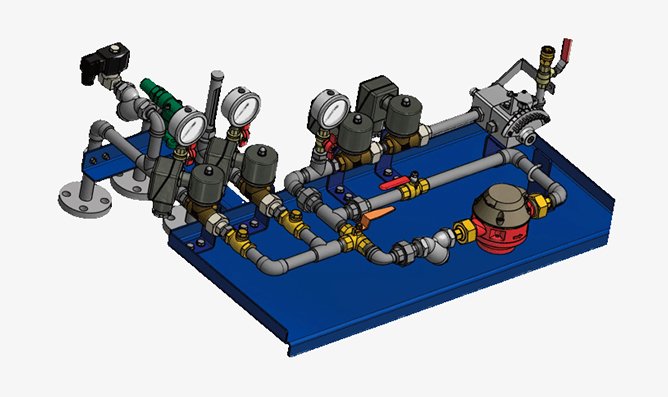

Upgrades

Upgrades are effective for improving fuel efficiency and user convenience for existing vessels

as well as new vessels.

-

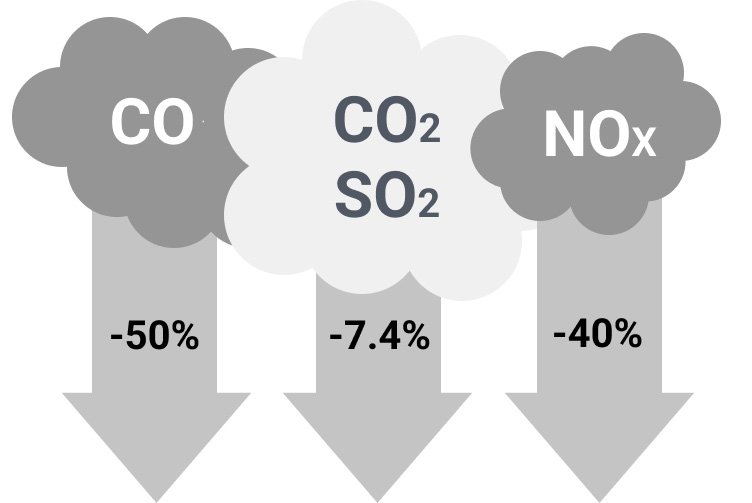

Emulsion Combustion

SystemReduces fuel consumption by 7.4% -

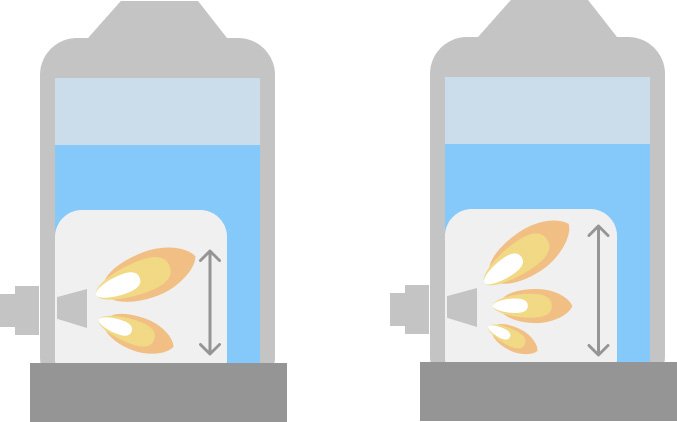

Turn-Down Ratio

ImprovementReduces fuel consumption by fine fuel control -

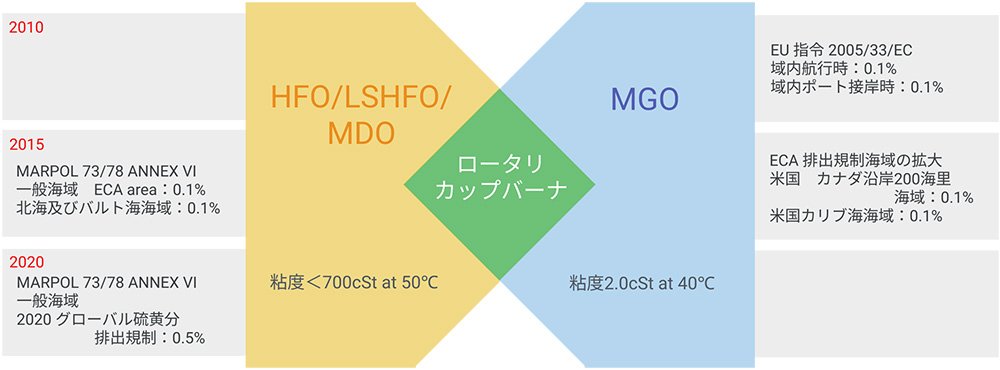

MGO Switch-Over SystemReduces fuel consumption by switching between fuels

-

Garbage FeederIncinerate solid waste during operation

-

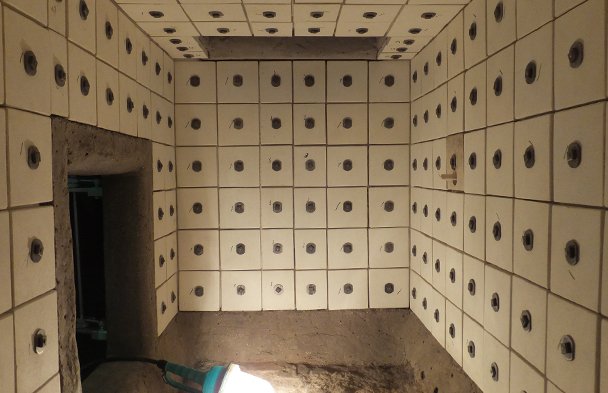

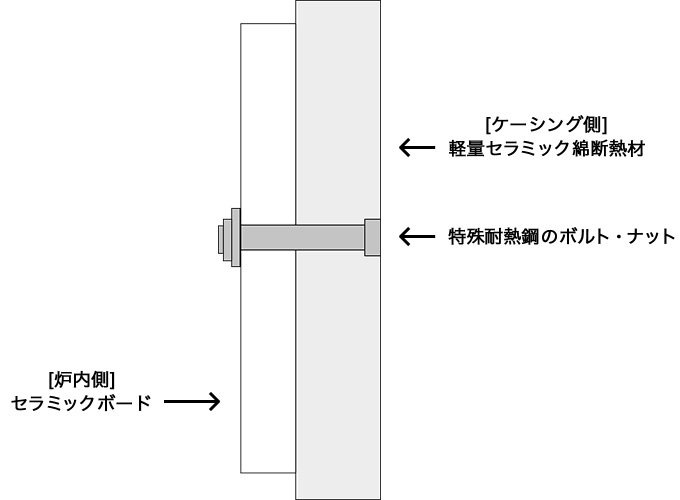

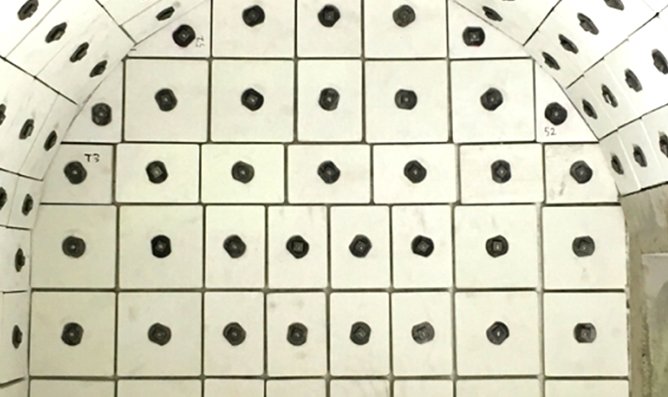

Ceramic Board RefractorySimplifies maintenance

-

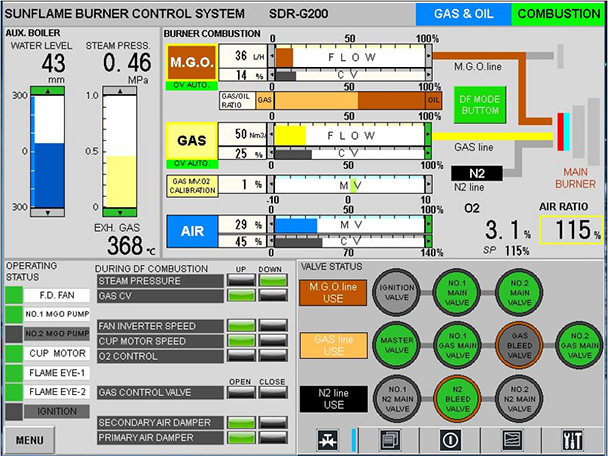

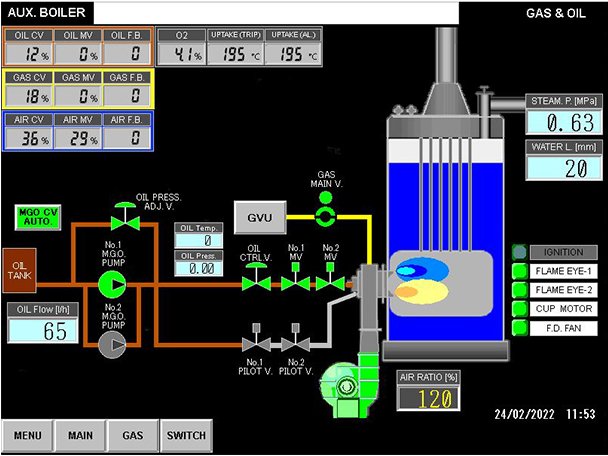

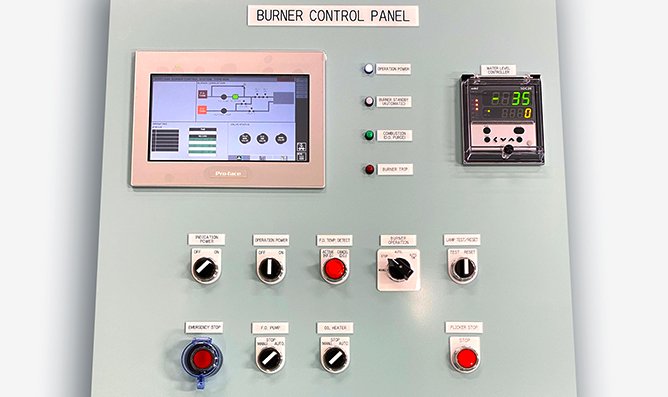

Touchscreen Control PanelVisualizes operational condition

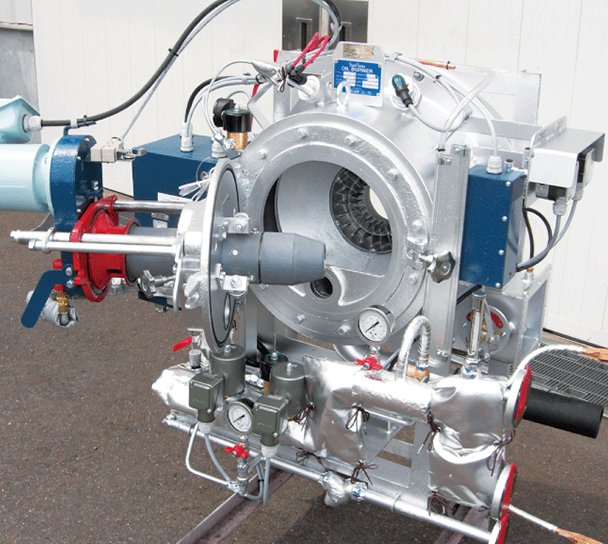

Repair and Maintenance

Depending on the condition of failure or malfunction, we will offer our best solution such as equipment overhaul at our shop or engineer dispatchment onboard.

-

Machine Check-Up

-

Overhaul

-

Maintenance

-

Machine Adjustment

-

Refractory Maintenance

-

Upgrades

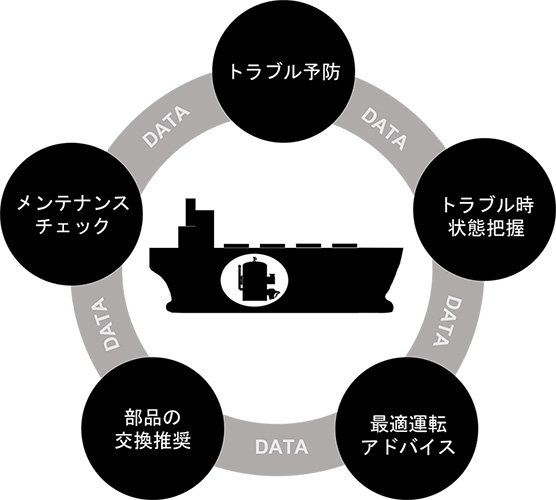

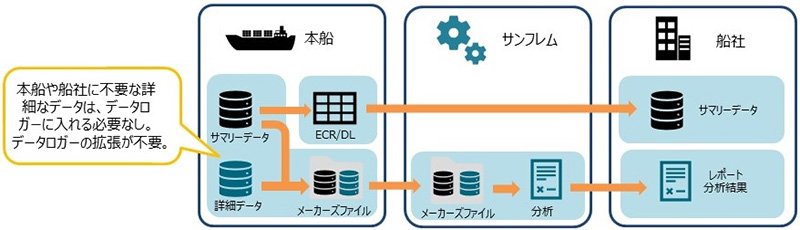

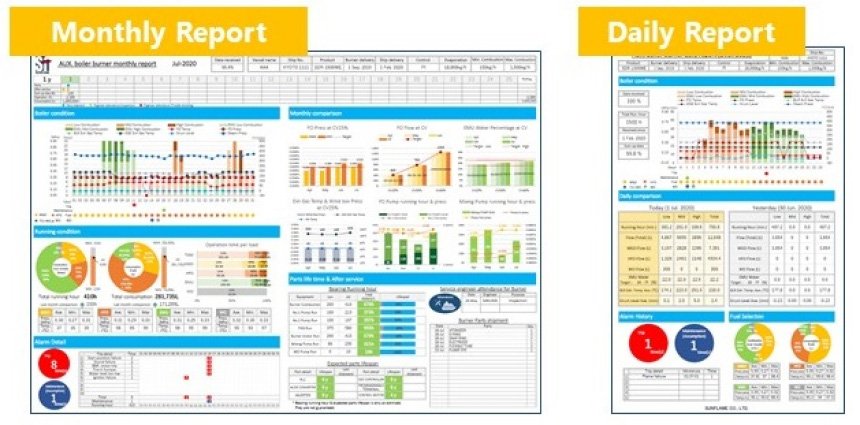

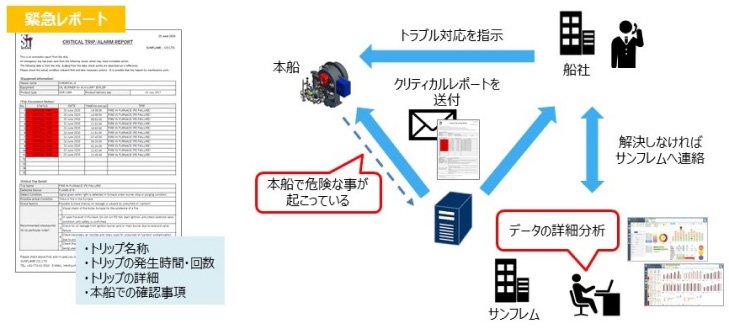

Smart Support

We monitor the operational data of Sunflame products to assist in troubleshooting and to suggest

maintenance at the optimal timing.

-

Sunflame

Smart Support SystemMaintenance Advice -

Operational ReportReceive boiler operation data daily and

monthly -

Accident PreventionReceive initial countermeasures when

high-risk accidents occur

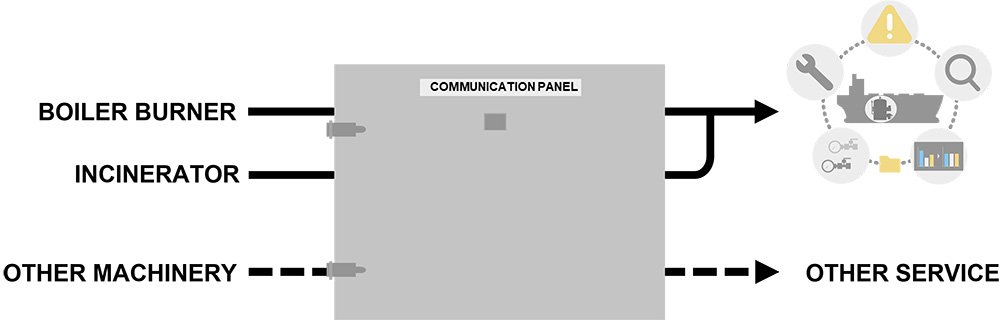

-

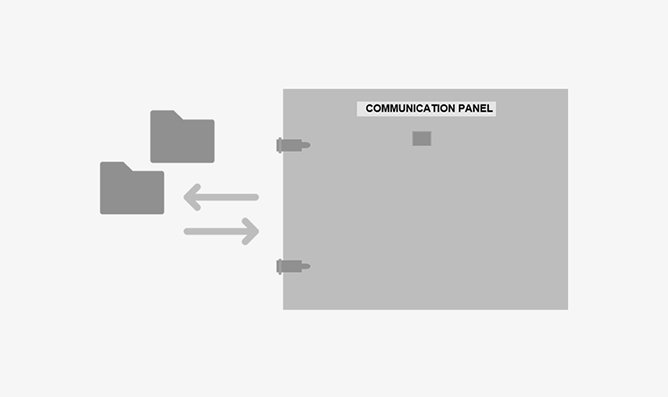

Data Collection and

ForwardingOperational data forwarding using

communication panels

After-Sales Service Network

We dispatch trained engineers from our service engineering bases across the world.